What do the Waterview Tunnel, City Rail Link, Auckland Harbour Bridge and the Christchurch Convention Centre all have in common? Their building service supports are constructed and seismically braced using the world’s most flexible, all-purpose metal framing system.

The manufacturer, Atkore Unistrut, opened a new state-of-the-art factory and distribution centre in Hamilton last week which will increase production capability and enable the design and manufacture of bespoke engineered solutions.

The opening also coincides with the company’s 100-year anniversary.

David Hardy, New Zealand General Manager, says the double milestone highlights the huge success the modular framing system has had in the construction industry over the last 100 years.

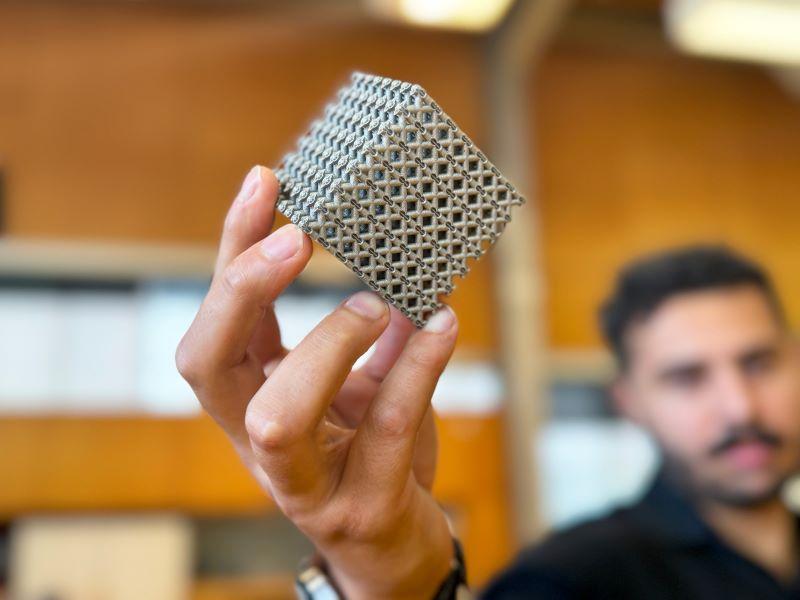

“Atkore Unistrut’s Strut System eliminates the need for welding and drilling. It is easily adjustable and reusable and is the industry standard to support heating, ventilation and air conditioning systems, cable containment, pipework and create seismic bracing systems,” explains Hardy. “There’s a little bit of Unistrut in every industrial and commercial building in New Zealand.”

“The new manufacturing and distribution facility will increase our capacity to serve the construction market across New Zealand allowing us to undertake larger and more complex projects within quicker time frames. This includes our ability not just to supply but to install our product as well. We have a dedicated construction team that supports contractors nationwide.”

The new $20million, 6000 square metre site at Horotiu, 13 kilometres north of Hamilton city centre, joins existing sales offices in Auckland, Wellington and Christchurch.

As well as the increased floor space to house additional machinery, including a $400,000 laser cutter, the new facility allows for the provision of prefab support frames and modular assembly for building services. With an inhouse mechanical engineer, Atkore Unistrut can also offer a portfolio of services, especially with seismic engineering.

“Even though Unistrut products are fundamentally used in industrial applications, in recent years, the trend for retail and cafes to have an industrial look with exposed services, Unistrut has played into that, providing not just a functional solution but offering an architectural style,” says Hardy.

“As the market leader in cable containment we manage the entire product lifecycle, from product design to manufacture and installation.”

With the company’s heritage founded in the United States, architect, Charles Attwood, came up with the ingenious concept, in the 1920s. He created a channel support system with curved pyramid edges followed by a spring nut with serrated slots. This resulted in a complete box section support that could be built into a frame support. The tightening up of these nuts would then allow more framing to be added to the original support, with the absolute certainty that the strut could not lose its shape.

From this original idea, it could be calculated what weight each section could support and if further support was required. No drilling was required, just the addition of more spring nuts and further lengths of Unistrut channel supports. This has proven to be an absolute game changer for the construction industry.

Having contributed to many of the country’s largest construction and infrastructure jobs, Atkore Unistrut is looking forward to its latest project – providing cabling containment and infrastructure components for the long-awaited Te Kaha Christchurch sports stadium. Product for the stadium and the new Dunedin Hospital will be among the first to be manufactured at the new Hamilton site.