For the fourth consecutive year, Bonfiglioli announced that the company has renewed its membership of APQP4Win, a non-profit collective of the world’s leading wind turbine manufacturers and suppliers. This organisation helps companies achieve better quality solutions for wind power generation.

“Bonfiglioli’s membership of APQP4Wind highlights the company’s commitment to a sustainable future, and its role in the development of the world’s wind industry,” explains Martin Broglia, Managing Director Bonfiglioli Australia and New Zealand. “That one out of every three wind turbines globally use a Bonfiglioli gearbox, tells me we’re on the right track!”

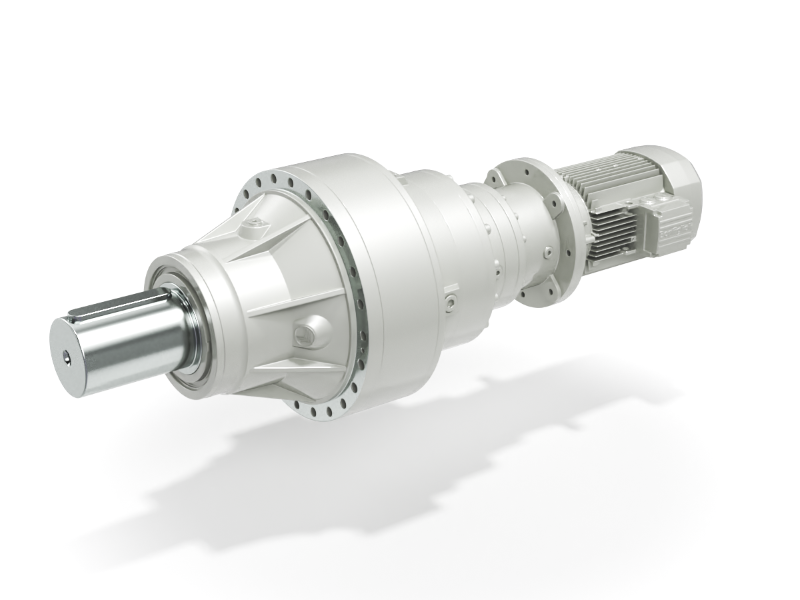

Martin points to the new 700TW Series planetary gearbox which is setting the standard for the growing wind turbine market. “This is the latest generation Yaw Drive planetary gearbox from Bonfiglioli, which offers reliable high radial/thrust load capacity and efficiency, in a robust and modular design,” says Martin.

This gearbox was recommended for use by Spanish wind energy company, Siemens Gamesa Renewable Energy, when it sought out a wind turbine generator that could sustain a greater load for use in its 5G5x turbine. This is an onshore wind turbine that can reach up to 6.2 MW of power with a large rotor, obtaining one of the most competitive LCoE (Lower Cost of Energy) feasible.

“This demonstrates that Bonfiglioli’s dedicated integrated wind turbine solutions – developed over more than 30 years of co-engineering and collaboration with the world’s leading wind turbine OEMs – deliver reliable, superior performance, to maximise the customer’s productivity and ROI”.

A planetary gearbox ideal for offshore wind projects

Setting a new standard for offshore wind gearbox products, the cost- and space-saving 700TW series yaw drive with integrated moto-inverter delivers high performance even in low duty cycles. It features a wide range of reduction ratios, as well as high transmissible torque, radial/thrust load capacity and shock resistance. With its rugged construction, including heat-treated steel alloy gears, this cost-efficient gearbox can handle heavy-duty applications with ease.

It’s 8% lighter than its predecessors, and smaller; the integrated AC motor flange and brake decreases its height by 20%. It boasts a simplified design, with only 2-piece housing and is IoT-ready, thanks to an in-built inverter.

“This gearbox is designed to reduce the lifetime cost of a wind turbine plant and offers improved energy consumption. It delivers great control both as a motor and as a generator, for regenerative braking action. In addition, it can be used as a battery backup solution. Installed and integrated with Bonfiglioli sensors, the solution provides real-time information on the load, speed and absorbed current of the system, making predictive maintenance easy,” explains Martin. “Bonfiglioli is the wind turbine one-stop shop, ensuring that customers enjoy the benefit of reduced complexity”.

: https://www.bonfiglioli.com/australia/en