By Matt Hale, International Sales & Marketing Director, HRS Heat Exchangers

Orange juice remains one of the most popular soft drinks around the world, but challenging weather conditions in 2021, 2022 and 2023 in the world’s major production regions of Brazil and Florida mean that the supply chain faces record raw material costs. As a result, producers will need to focus more than ever on production efficiencies in order to maximise margins.

The good news is that the demand for orange juice remains high, despite consumers in some markets, such as Europe, moving away from fruit juices and related products as they are perceived to be relatively high in sugar and calories. This fall in demand has been compensated for by increasing demand from food processors for the production of smoothies and flavoured water, which are generally perceived as healthier choices. Demand for straight orange juice also received a significant boost from the Covid Pandemic around the world. Overall, most analysts predict level, or slightly increased worldwide demand for the next few years.

Production challenges

The trouble for the industry is that despite this buoyant demand, the last couple of years have seen reduced fruit output from the major production areas of Brazil and Florida. Other less important producers are also struggling, with European production also down this year, in line with a longer-term trend.

Brazil, the world’s largest grower of citrus fruit, suffered significant frosts and droughts during the 2021 growing season, but production is projected to bounce back by 20.5% to 317 million boxes1 for the 2022/23 season2. However, the final effects of a warmer winter season, which saw higher than normal levels of fruit drop still have to be assessed. At the same time, lower-than-normal stocks from 2021/22 have kept local prices high (up to 50% higher in July 2022 compared with the previous year).

In contrast, production from Florida (the second largest producer of citrus in the world) is estimated to fall 62% for the 2022/23 season to just 15.7 million boxes.3 This represents the largest fall in production in 110 years. The reasons for Florida’s reduced production are related not just to weather (orange groves have suffered damage from hurricanes, frosts, and insect damage), but also to citrus greening disease, a bacterium which causes fruit to shrivel and fall from the tree before it is ripe. The number of Valencia orange trees in Florida has also fallen from 36 million in 2006 to just 30 million today as real estate and land prices in the State persuade many growers to cash in the value of their land.4

Difficult markets

It’s no wonder markets are nervous, with orange juice futures matching historical highs in New York at the end of 2022 with increases of 50% or more compared to the previous year. According to some estimates, US orange juice production alone will fall 6.5% to 215,000 tonnes for the current year, although stocks of juice are expected to remain stable.5

All of these factors mean that orange juice producers, whether using concentrate or frozen not-from-concentrate (NFC) juice, face an increase in raw material costs of around 50%. Add this to the global energy crisis following Russia’s invasion of Ukraine, which saw energy prices rise as much as 60% for oil and 400% for natural gas in Europe (although prices at the start of 2023 were much closer to pre-invasion levels), and producers are in the front line of food inflation.

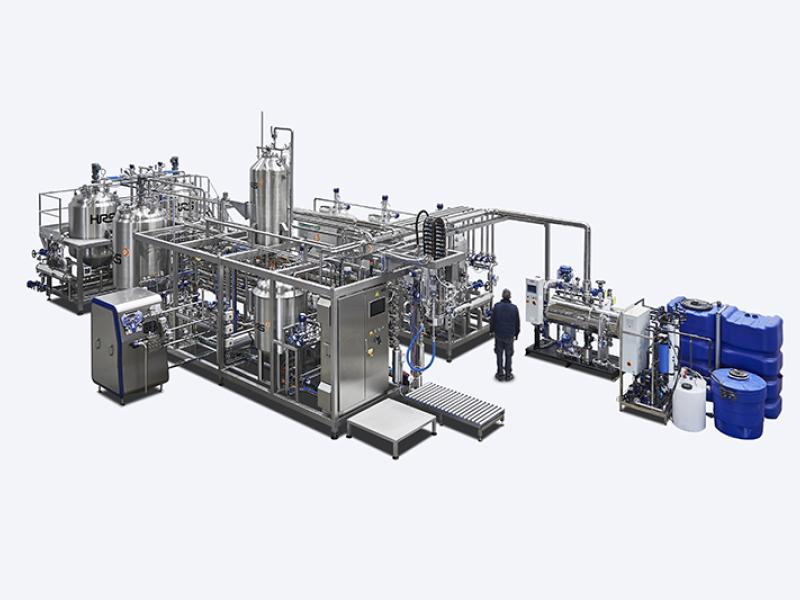

Faced with unavoidable rises in input costs, not all of which can be passed on to customers or consumers, manufacturers must make every effort to maximise the efficiency of processes such as remelting and pasteurisation. At the same time, they need to maintain the key quality characteristics of the juice, even though chemical changes begin as soon as the juice is squeezed. HRS Heat Exchangers produce a range of highly energy efficient equipment for orange juice processing.

Pasteurisation options

Thermal treatment, sometimes known as ‘flash pasteurisation’ is the preferred technique for making premium juice. The HRS MI and MR Series of pasteurisers use food-grade, multi-tube, corrugated heat exchangers to speed up the heat transfer in pasteurisation systems. These corrugated tubes create extra turbulence in the fluid as it flows through the tubes.

This extra turbulence means that the orange juice can be heated up to pasteurisation temperature much faster – typically by up to 30%. Because of the high heat transfer rates of the corrugated tube technique, HRS’s pasteurisation systems use water at a lower temperature to reduce the risk of product damage. Another benefit of higher heat transfer rates is that the system footprint can be reduced by using shorter heat exchanger pipes. The shorter length of the heat exchanger also results in a reduction in pressure drop, which saves pumping power and further reduces energy costs – often by 40%.

One issue with flash pasteurisation is that it still takes time to evenly heat the product, adding to the total processing time and increasing the risk of adversely altering the product’s organoleptic properties. In contrast, ohmic heating, which uses electricity to heat the product rapidly and uniformly, has been scientifically shown to be highly effective while maintaining flavours and quality.

The HRS ohmic system works by passing electricity between two electrodes in the product in a 1m ceramic tube, so the electricity has to pass through the product. The result is that the juice is heated up to 105 °C within one second. It is then held at this temperature for four seconds before being cooled. Ohmic technology itself is not new, but the HRS system uses the latest electronics to ensure that the temperature curve is very smooth, which not only helps to preserve product quality but also improves process efficiency.

Raw material handling

The HRS I Series offers options to de-pack and crush (the IC Series) then melt (IM Series) frozen fruit juice (a process also sometimes known as re-melting) ready for storage or further processing. The IC Series features a roller conveyor which feeds individual drums into a tipper that empties them into the crusher. Here, a specially designed spiked roller crushes the solid ice into an icy slush, which is then transferred to the IM Series re-melting device.

Based on the tubular heat exchanger technology for which HRS is renowned, the IM Series raises the temperature of the juice from frozen to around 4 °C in 90 seconds. From here, the cold liquid juice can be pumped to a holding tank, or straight into the next process step.