In an era where manufacturing and process plants are under increasing pressure from soaring energy bills and ever-tightening CO2 emissions legislation, it begs the question: is there a way to reduce energy consumption – quickly - without compromising efficiency or output? The short answer is yes; but only with the right advice and expertise.

Recently, SMC Corporation shared an article on a hot button issue in factories the world over: energy savings.

“We have spoken to this topic time and time again, but knowledge and information continues to evolve and with it, comes further insights and advice for our customers,” says Bill Blyth, Group Manager ANZ Energy Conservation for SMC Corporation ANZ.

“In his article, we detail five pertinent ways to ensure energy savings, all of which are relevant to our customers in Australia and New Zealand.”

Five ways to deliver fast and effective energy reductions

1) Relieve the pressure

The first way is to reduce the pressure of the compressed air system, where possible. For most industrial plants, typical operating pressure is between 6 and 7 bar. By lowering your pressure to 4 bar, energy consumption reduces by up to 29%. However, expert input is required to avoid compromising performance.

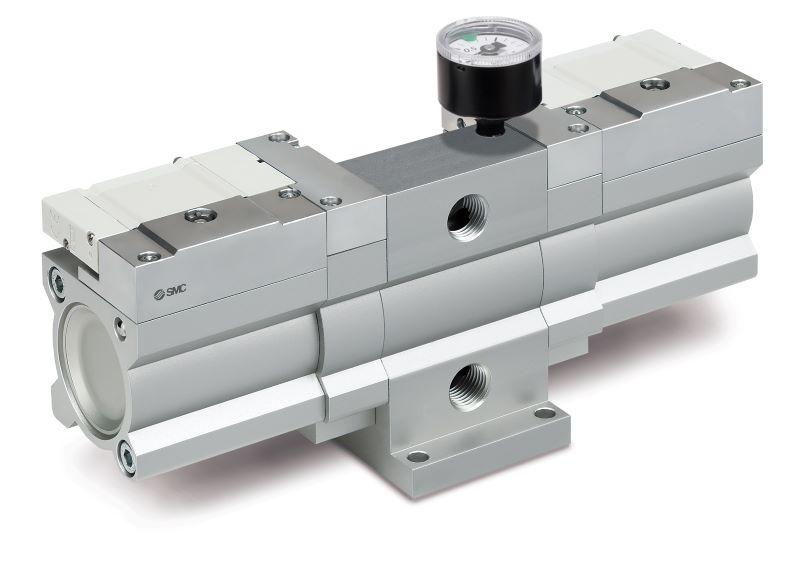

“For those seeking a quicker route to improvements, shut-off solenoid valves help prevent air losses, caused by leaks - even when machines are idle. Other solutions include a two-pressure module that switches to a lower pressure during machine idle periods, vastly reducing air leakage, or the new plug and play Air Management System (AMS series) by SMC,” comments Bill.

2) Plug leaks

SMC have encountered plants suffering from 20 to 50% leakage rates, driving up energy consumption and bills. The optimal way to identify leaks is by appointing an expert company to undertake an audit, ideally twice a year.

“SMC’s main line filter series, the AFF, is the ideal solution,” says Bill. “It offers an increased air flow capacity due to the lower pressure drop, contributing greatly to one’s energy saving. It also offers a flow capacity of 14.5min (ANR) and pressure drops of 5kPa or less.”

Other complementary recommended products include SMC’s range of S couplers (the KK130 series), the TKS double layer tube stripper and the TRB/ TRBU series of double layer tubing.

3) Blowing applications

Did you know that air-blow tasks are accountable for more than 40% of your factory air consumption, thus offering a real savings opportunity? Here, sizing your blow nozzles correctly, coupled with a reduction in factory pressure, delivers good results. Further initiatives in this area include better use of regulators to ensure you only use the amount of air necessary. Pulse-blow valves, which switch the air blow on/off very quickly while maintaining the force of the blow, offer another great way to reduce your air consumption, sometimes up to 50%.

“SMC offers a range of components for efficiency in air blowing applications. These include the KN series of nozzles for blowing, the ever-popular VMG blow gun, the IBG compact type blow gun series, the IBV10-X5 impact blow valve and the AXTS series of pulse blowing valves.”

4) Efficient vacuum systems

If you have machinery using air-generated vacuum pick and place applications, the use of vacuum ejectors with multiple Venturi and air switch-off energy-saving technology reduces air consumption by up to 93%.

“SMC is dedicated to enhanced savings through our vacuum ejector range,” comments Bill. “The ZK2A vacuum ejector series is an energy saving ejector which cuts off air supply once vacuum is reached. The ZL3 series is a multistage ejector is a high-efficiency vacuum generator, operating at around 150%. Finally, the ZKJ vacuum manifold series is designed to reduce air consumption by 90% and is Fieldbus-compatible.”

5) Right components

We always say at SMC that energy and cost efficiency is deliverable through many small actions. Choosing components wisely makes a big difference. For example, adding power-saving circuits to your solenoid valves, a speed controller, such as the AS-R series, to your cylinders or using triple inverter technology in your thermo-chillers such as the HRSH inverter type, helps to ease energy bills.

“With the right advice and components, energy savings can be quickly and easily achieved,” says Bill. “SMC’s range is able to deliver on all five energy saving mandates, and our team is ready to help you achieve long-term savings.”