The mechanical properties of composites, such as their weight, stiffness, and strength, are normally the deciding factor in the design process. However, in applications where there is a risk of encountering fire, smoke, and toxicity (FST) conditions, this becomes the primary consideration when specifying composite solutions. To help companies operating in key industries, including transportation, building, construction, and infrastructure, navigate FST requirements, pultrusion and pull-winding expert Exel Composites has released its FST whitepaper to explain how fire considerations influence composite designs.

Exel Composites has created a guide to FST for composites, sharing key details about FST considerations. This whitepaper explains how fire considerations influence composite design and discusses the practicalities of what this means for industries such as transportation and building, construction, and infrastructure.

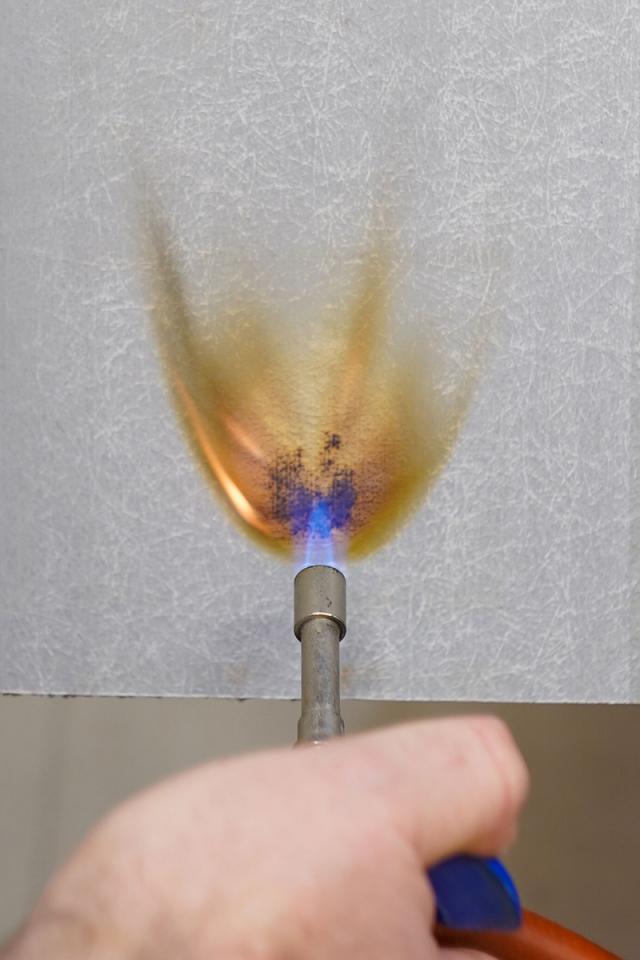

“With the use of composites in demanding applications increasing, improving knowledge of their fire performance is becoming a safety-critical issue, particularly for building and transportation applications,” explained Eric Moussiaux, VP technology at Exel Composites. “Generally, there are three main fire performance considerations for manufacturers. These are how difficult it is for the material to ignite, how fast the fire spreads, and how much heat it generates. Next, how much smoke will develop and how quickly? Finally, how toxic is the smoke and how quickly can it cause harm? These considerations are typically referred to as FST: fire, smoke, and toxicity properties.

“With these considerations in mind, it is common for composites manufacturers to incorporate flame retardant additives into the materials, reducing or delaying the combustion process. The nature of these additives varies depending on the application in question and any relevant regulatory requirements,” continued Moussiaux.

Exel Composites’ new whitepaper explains how, when specifying composites for applications where fire must be considered, a balance must be struck between the desired mechanical properties and meeting the relevant fire safety tests. While this might initially seem like a daunting prospect, this challenge can be overcome by working with a knowledgeable partner who understands all these considerations and can propose the most suitable solution available.

“Take train transportation, for example, here fire requirements vary depending on whether the train will travel overground or underground and whether the composites will be used internally or externally. In Europe, trains have three hazard levels and, as we move up through them, the level of FST requirements increases. This is just one example where we regularly hear from customers that navigating all the necessary FST requirements and knowing what tests to apply can be extremely complicated,” concluded Moussiaux.

To find out more about using FST requirements when specifying composites, visit Exel Composites’ website today to download the whitepaper.