~ Robotic solutions for when six axes aren’t enough ~

The 2021 World Robot Report released by the International Federation of Robotics estimated that there were roughly three million industrial robots in operation as of 2021, an increase of 300,000 since 2020. Manufacturers are incorporating robots into their operations at a significant rate, and given the many benefits that industrial automation has, this is only set to increase.

With this growing popularity, industrial robots are available in a huge range of configurations and sizes, with different numbers of axes for a range of applications. Robots can move on anywhere between one and seven axes, with more axes offering more flexibility of movement. However, despite the growing accessibility of robot in industry, it can still be difficult to know which type of robot out of the many now available is the best choice for an application.

Traditionally, when someone thinks of an industrial robot, they will picture a robotic arm. These are articulated robots and can mimic the actions of a human arm thanks to their directional control and large range of movement. Other types of robots, such as Cartesian robots or four-axis models such as SCARA robots are more limited, often only able to move on two to four axes. These robots are suited to many applications and certainly have their benefits, but the restrictions on motion can be an issue when more sophisticated movements are required. This is when an articulated robot is a better option.

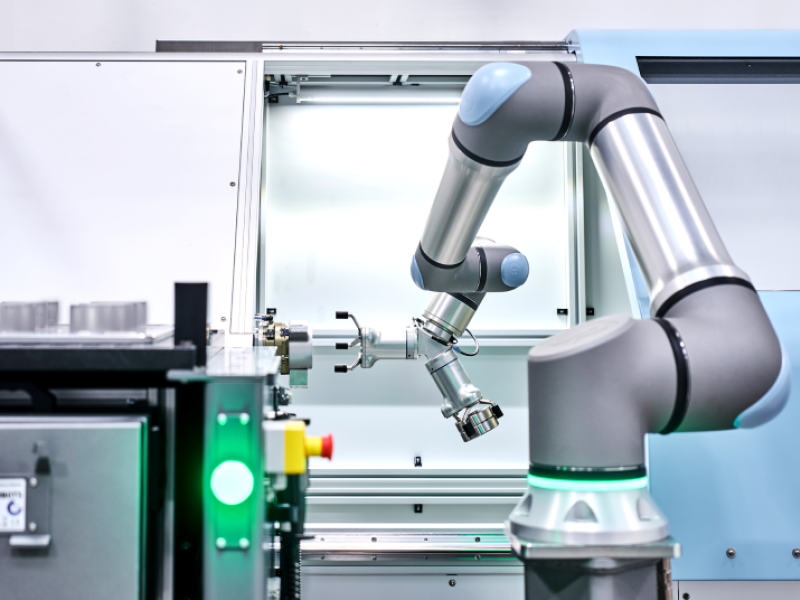

Articulated robots, including six and seven-axis robots, can move vertically and horizontally, but are also able to roll, pitch and yaw —they can rotate around the X, Y and Z axes. This gives them additional range and flexibility. They are typically mounted on a pedestal, with articulation points in the base, body, arm, shoulder, and wrist. This also allows them to work at differing levels and between planes, offering more versatility of motion sequence. Articulated robots are more capable of intricate or complex processes such as automotive assembly due to this ability to accurately manoeuvre.

Articulated robots with multiple axes are known as high degree of freedom (DOF) robots. These robots have a multitude of potential applications, including welding, assembly, pick-and-place, packaging, painting, and palletising. They can be used for handling and material removal, along with machine tending tasks. Articulated robots are often more costly, and their increased complexity does make programming more challenging, but the productivity and efficiency gains and long-term financial savings provide a good return on investment (ROI).

Six-axis robots can be used for all of these applications and are currently the most commonly used type of industrial robot. Though six axes are sufficient for most industrial applications, the increasing complexity of the tasks required of them means that the robots themselves must become more sophisticated. Seven-axis robots have the same axes as six-axis robots, but the additional degree of freedom allows them even greater flexibility.

There are two different primary configurations for seven-axis robots. The additional axis may be located within the robotic manipulator arm, or it may be in the form of a robot transfer unit (RTU), a track along which the robot is able to move. Though an additional axis is not always essential, the greater choice of joint configurations that comes with it makes a robot more manoeuvrable and can save time in terms of repositioning.

The seventh axis allows the robot to move in more complex ways, which is beneficial for intricate tasks such as welding where working from an appropriate angle is key for output quality and consistency. The robot can approach the product or workspace from a wider range of angles that operatives or six-axis robots may not be able to achieve, which can be considered when programming and used to reduce cycle times and use less physical space within a workshop. This also allows the robot to move and rotate around obstructions and equipment, avoiding collisions and potential damage to the robot or the surrounding environment. The ability to move around objects also removes the need for effector adjustment and gives greater tooling stability.

The addition of an RTU as a seventh axis has the added benefit of the robot travelling linearly over much longer distances. The RTU can move the robot between workstations and equipment, or across the full workspace to carry out different tasks. Operators can then automate a series of processes in sequence using the additional mobility from the track system using a single robot rather than a series of individual units.

Though articulated robots tend to be more costly than their linear counterparts, a seven-axis robot can be cheaper and more straightforward to integrate into an existing operation depending on the required system, as it can reduce the need for additional equipment such as robotic positioners. Their superior manoeuvrability can also help to improve cycle times and productivity. While there is no substitute for a reliable parts supplier like EU Automation in reducing equipment downtime, an investment in a seven-axis robot has the added benefit of avoiding costly downtime through damage and repositioning.

Though six-axis robots are the most common choice for industrial applications currently, seven-axis robots are increasing in popularity — and it is easy to see why. Seven-axis robots offer all the benefits of traditional articulated robots, but with an additional degree of freedom and superior flexibility. For complex tasks and processes, a seven-axis robot can offer long term productivity gains and the versatility to suit a range of applications to a consistently high standard.