Bonfiglioli prides itself in their relentless commitment to excellence, innovation and sustainability. The team creates, distributes and services world-class power transmission and drive solutions to keep the world in motion.

Recently, the Helical Bevel Gearmotors from Bonfiglioli has been gaining popularity in agitating applications around New Zealand.

According to Neil Pollington, Country Manager for Bonfiglioli New Zealand, the company has seen a particular good uptake of this product in local quarries and similar industries.

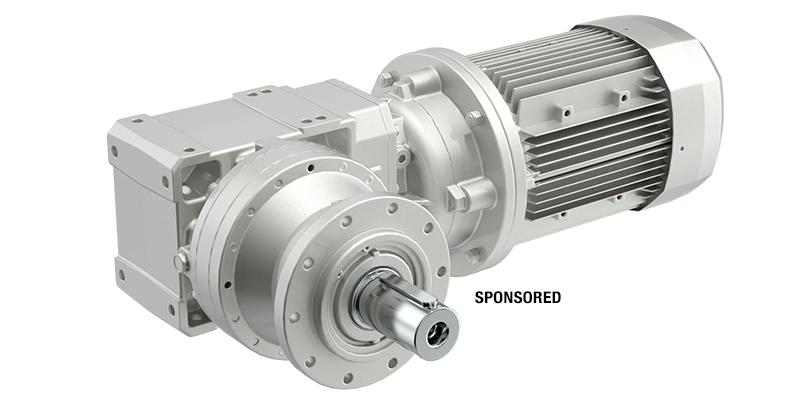

The A Series combines high efficiency and reliability, low maintenance costs and a wide torque range. This unit is particularly compact due to the right-angle layout between the input and output, and the compact motor coupling, which makes it suitable for applications where minimized mounting space is required.

Reduced standard backlash and a wide output speed range means this unit can operate safely in a wide selection of environments.

Further motor options such as thermistors and thermostat sensors, independent forced cooling, incremental encoders and anti-condensation heaters are just some of the additions which are available on this product.

The mechanical rating is from 0.22….150kW with a torque range of up to 14 000 Nm. The ATEX option is available, making this an ideal product for explosive environments.

Main options which make this product particularly attractive include:

- Surface protection of up to C5

- Reinforced bearings

- Reduced Backlash

- Torque Arm

- Fluor Elastomer oil seals

- Double oil seals on input

- Taconite seals

Feet and shaft mount with two bore options per size as well as a solid shaft, splined hollow shaft, hollow shaft with shrink discs are available on this model.

Neil elaborates that the company is committed to local manufacturing and the economy. “We have invested heavily into our local stockholding, to the value of NZD$2.5 mil. This ensures that we are well placed to assist customers with quick deliveries and a range of available spare parts” says Neil. The complete range of A series products to suit IEC motors from 0.18kW to 75kW in hollow keyed bore output, shrink disc output and solid shaft output is available from the local assembly plant.

Thanks to an international network of sales branches and closely interconnecting production plants, the company guarantees the same high standards of Bonfiglioli quality anywhere at any given time. You will receive the same quality and level of service whether you be in Italy, Germany, New Zealand or anywhere else in the world.

The company ascribes their direct presence in local markets is the key to long-lasting success. This includes 22 sales branches, 14 production plants and more than 500 distributors around the world.

In Auckland New Zealand, Bonfiglioli offers local assembly, spare parts and service to customers across the region.

The New Zealand team includes three full time fitters assembling these and other products in Auckland. "Customers in New Zealand can therefore rest assured of quality products available in quick turnaround times" concludes Neil.