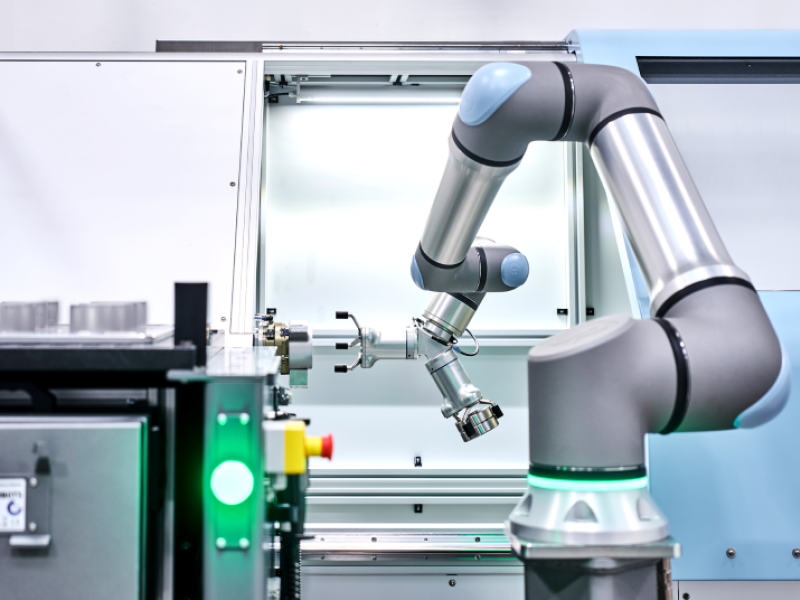

It travels across a warehouse grid at speeds of three metres per second, easily handling 650 bin presentations every hour, and carrying large 425 mm-high bins with ease. This is the R5+ Red Line Robot – the latest in the R5 series, launched in February last year by AutoStore. It features class-leading energy efficiency: Ten R5 Robots use less energy than the average vacuum cleaner.

“24% of Asia Pacific respondents in AutoStore’s 2022 State of the Market Industry survey cited rising energy costs as a major business challenge. For a further 34% of respondents, labour challenges are cited as a significant hurdle,” notes Jason Wu, Business Development Manager for AutoStore Australia and New Zealand.

The R5+ Robots present the local market with a formidable solution, as they work around the clock and are energy efficient, supporting high throughput as they complete tasks faster than manual labourers. “The implementation of the R5 and R5+ is a significant factor in the 99.7% uptime achieved across the AutoStore installed base,” adds Wu.

“Our Robots bring goods to pick stations instead of people needing to walk to storage locations,” he says. “These independently controlled Robots pick and deliver fast, giving warehouse owners access to 100% of their stock, as and when needed”. In so doing, these Robots reduce the need for human workers to carry out warehouse functions, lowering labour costs. They also improve the speed and efficiency of the retrieval process, in turn boosting warehouse productivity.

Over the last 20 years, the R5 series of Red Line Robot has proven its efficacy, rapidly retrieving, and delivering items within Automated Storage and Retrieval Systems (ASRS) installed in warehouses across the globe. This compact Robot enables highly productive, efficient, and accurate order fulfilment in a variety of warehouse settings, including retail, industrial, manufacturing, and pharmaceutical.

Low energy consumption and low maintenance requirements

With their low energy and maintenance requirements, these Robots deliver a comparatively low total cost of ownership.

“These Robots are extremely energy efficient,” explains Wu. “They use regenerative technology that returns energy to the robot battery. This feature makes the AutoStore system one of the only systems that can run on solar power alone”. In addition, the Robots can run for approximately 20 hours before requiring charging, and are programmed to do so at opportune moments, such as during periods of low activity.

Intelligent goods-to-person operation

Aside from being energy efficient, these Robots are designed to optimise the retrieval and delivery of items, enabling reduced picking times. “They complete the closest task, using the shortest route,” notes Wu.

The R5 Robot has demonstrated its efficacy in a wide variety of warehouse settings, accurately picking, sorting, and retrieving items with speed. “In reducing the need for human labor, and also enhancing capacity and reducing downtime, these Robots enable cost savings and improved performance for businesses of any size,” concludes Wu.

About AutoStore | www.autostoresystem.com