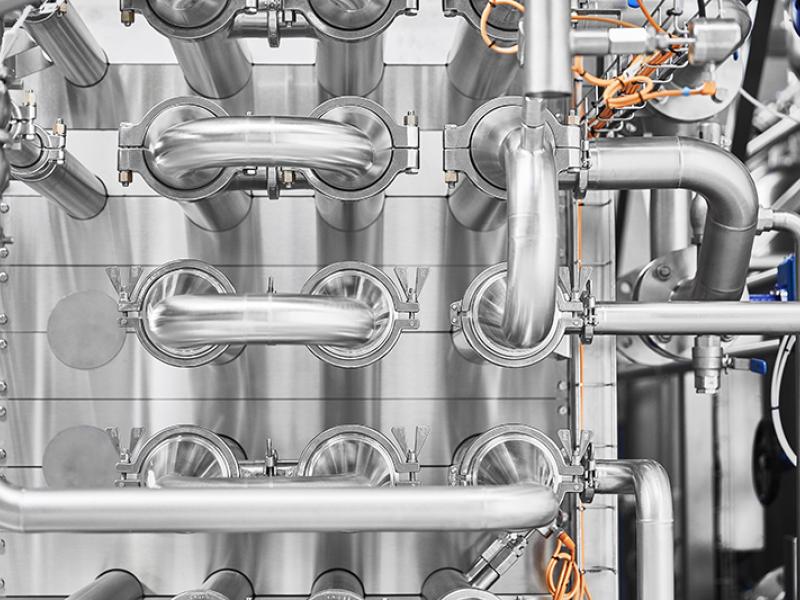

ANZCO recently commenced a multi-stage plant upgrade, with the first stage being the beef tripe line. Included in the project were the installation of new hot and cold water feeds and compressed air lines. These were located both externally and internally within the processing building.

The pipework installation was undertaken by Menzies Plumbing from Timaru.

The project was undertaken during the plant processing season. This meant that the pipework installation had to be completed within a very tight schedule to eliminate any interruption to the plant’s operation.

ANZCO had previously installed Kembla’s KemPress stainless steel press fit tube system in other parts of their plant, and have now standardised on it for their water and compressed air lines throughout the plant. Having KemPress used for the beef tripe line was important for ANZCO as they can easily maintain and add to the line in the future if required. Another key consideration for ANZCO was that the pipework selected for the project could had good weather and UV resistance, allowing it to be used both internally and externally.

With the pipework needing to be installed over a weekend, speed and ease of installation was critical to Menzies. Being able to eliminate the need for hot work permits and a fire watcher while joining the pipework would also ensure the work could be done within the project schedule.

The speed of installation and the flame free jointing process of the KemPress piping system made it an ideal choice. Owen Kershaw, Menzies plumber who did the installation, commented that the KemPress “easy and quick to install” and took less than half the time compared to installing other types of pipe materials that they have used in the past on similar projects.

To meet the tight deadlines, Kembla worked closely with both ANZCO and Menzies Plumbing to ensure that the tube and fittings were on site in time for the weekend installation. The water and compressed air lines were installed and commissioned over one weekend, ensuring the plant restarted on time for the new shift.

ANZCO’s Asset Manager, John Corcoran, also commented on how tidy the pipework installation looked.

Contact 09 274 0111 or email sales@kembla.co.nz