Over the years, safety has become a top priority for many organisations; not only to protect the wellbeing of employees but also to enable enhanced safety outcomes. As a leading automation specialist, SMC Corporation Australia New Zealand (ANZ) understands the fundamental role that it plays in protecting people and systems, and prides itself on being a holistic solution provider, rather than a component supplier.

“We speak the safety language,” comments Shyam Suresh, Global Accounts Manager for SMC New Zealand. “Our end goal is to improve equipment and avoid accidents. When it comes to safety, we always take a proactive approach by identifying any potential problems or threats, specifying the right product for the job, and walking the journey from the design phase right through to installation and testing.”

Responding to the uptick in demand for applications requiring safety components and expertise, Shyam recently obtained a CMSE- Certified Machinery Safety Expert qualification to further benefit SMC’s customers. “This globally recognised qualification enables a 360° approach to machinery safety – a unique differentiator in the market,”

“Safety is on everyone’s mind. Thanks to CMSE, coupled with our quality range of safety products, we can confidently work alongside our customers and their safety teams to ensure that ISO standards and general safety compliance standards are met.”

In addition, Shyam looks to empower his colleagues through his learnings. “Shared learnings, coupled with our safety-enhanced product range ensures that we are perfectly positioned to offer safety expertise to our customers.”

Shyam’s top tips

When it comes to safety on the factory floor, Shyam shares three tips as follows:

1) Training: “Staff need to be adequately trained on the products and processes being rolled out on the factory floor. This forms the basis of a safe factory environment.”

2) Improving equipment: “Having safe equipment is a must. These days, products have been IIoT enabled to include visual monitoring and real-time reporting for enhanced safety and energy savings measures.” While Shyam acknowledges that not every company has the budget to upgrade its entire system, incremental upgrades are also an option. “We understand that a full plant upgrade cannot simply happen overnight, and we walk the journey with you from start to finish.”

A safe environment: “Looking to the environment at large, companies need to check that 1) staff are adequately equipped with PPE, 2) that safety measures are being followed, 3) that staff are not overexposed to risks, such as high noise levels.”

Not all heroes wear capes

Shyam highlights two SMC safety heroes in the range as follows:

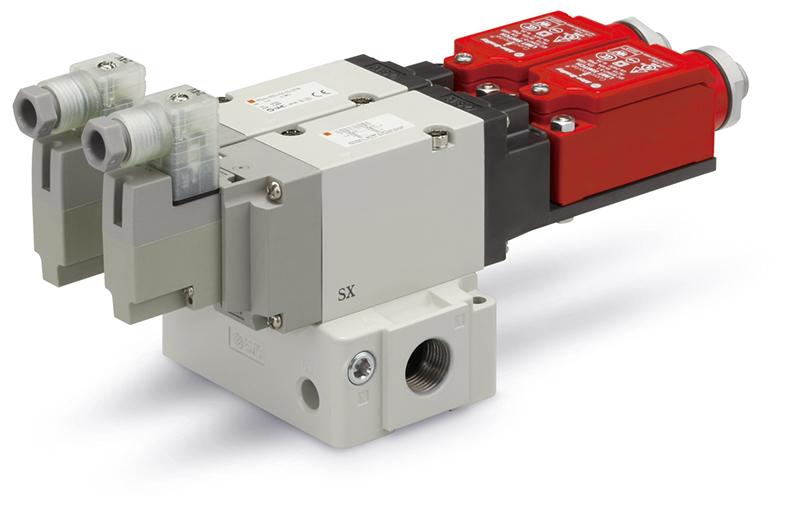

The VP series

SMC’s VP300/500/700 series of solenoid valves - best-known as dump valves – offer high flow capacity and reduced power consumption. The VP series is a 3-port residual pressure release valve which features detection of the main valve’s position. “This reliably constructed valve complies to ISO 13849-1 (and Category 1 to 4), and features an easy-to-construct redundant system. Customers can also select a variety of safety limit switches. A soft start-up function (-X555) can also be added.”

The JXCLF series

Any machine builder looking to simplify and reduce the cost of adding higher levels of safety, while simultaneously seeking faster and broader communication capabilities should consider the new JXCLF step motor controller from SMC.

The JXCLF features an IO-Link communication interface and a Safe Torque Off (STO) function, thus presenting machine builders with the opportunity to deliver better control of the manufacturing process and increase their system’s safety integrity level (SIL 3) and performance level (PL e) in a cost-effective way.

PneuSAFE

As a general guide, there is a software tool from SMC called “PneuSAFE”; it lists a wide range of safety products by application or function. “With a comprehensive list of functions and applications, you’ll quickly find your way to the circuits you require, all of which have been confirmed to meet the stated ISO 13849 category and performance level.”

To conclude, Shyam says, “through SMC’s safety-first approach to employee wellbeing and our safety-enhancing products, SMC is well-positioned to support the market at large.”

Website: www.smcanz.com

For sales enquiries please contact AUsales@smcanz.com or NZsales@smcanz.com