Mixing a variety of I/O interfaces with an FPGA on one XMC module to deliver flexible signal processing and high-performance computing.

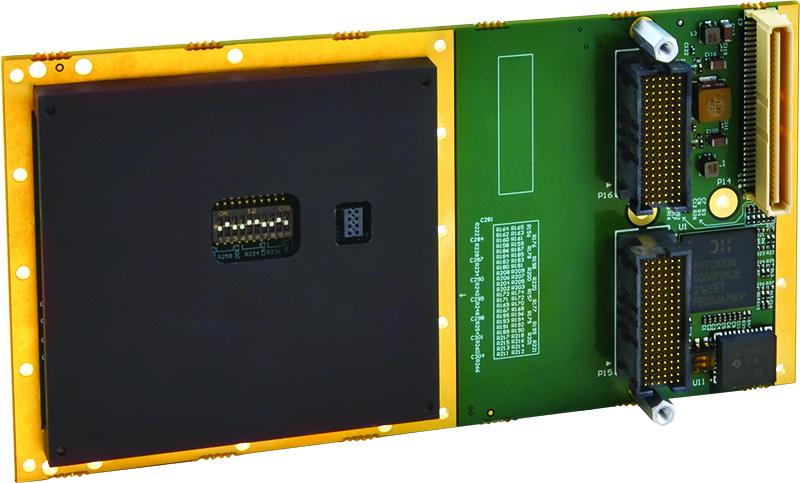

Acromag’s new XMC-7A50-AP323 provides a user-customisable Xilinx® Artix®-7 FPGA with 48 TTL I/O channels plus a 16-bit ADC for 20 differential or 40 single-ended analogue inputs on an XMC module. These high-performance modules are for embedded applications running on Linux®, Windows®, or VxWorks® operating systems.

The XMC-7A50-AP323 offers a wide operating range of -40 to 70°C and conduction cooling options. The FPGA digital I/O offers 32Mb quad serial flash memory with 52,160 logic cells. Reconfiguration of the FPGA is possible via a direct download into the Flash configuration memory over the PCIe bus.

The high-density GPIO initially supports TTL but can also accommodate LVDS and RS422/485 signals. Flexible A/D conversion allows configuration of analogue input voltage ranges, scanning modes, and interrupts.

Acromag offers a variety of I/O signal processing functions plus the power of a configurable FPGA on a single XMC module to meet demanding SWaP challenges. Other custom I/O interfaces with an FPGA on one XMC module are available by request.

Designed for COTS applications these XMC modules are RoHS compliant and ideal for scientific development labs, military and aerospace applications, the defence industry, and automation applications.

For Further information, please contact: www.metromatics.com.au