Lubrication of bearings is an essential part of machine maintenance and is a critically important process for keeping the machine running and to extend bearing lifetime. However, how do you know that your bearings are lubricated at optimal levels? We do not want to under-lubricate bearings and nor do we want to over-lubricate them.

With the Adash Lubri tool, it’s simple. The Lubri is a maintenance tool used for monitoring and control of the lubrication process.

The Lubri measures the actual bearing lubrication status and informs the operator when the lubrication state is optimal. It does this by comparing bearing vibration levels before during and after grease is added.

Lubri measures actual bearing vibration once the sensor is mounted on the bearing house. Keep pumping the grease and see the vibration value going down. The bearing is well greased once the vibration value is not decreasing anymore. Extend your bearings lifetime as simply as this!

Headphones can be connected to listen to the bearing condition. The Lubri is simple to operate and also enables you to perform basic measurements and diagnostics of bearing condition, storing results of measurements for reporting, and trending of overall bearing and whole machine body vibrations.

Machine routes can also be loaded onto the Lubri to ensure consistent and comparable results.

How it works:

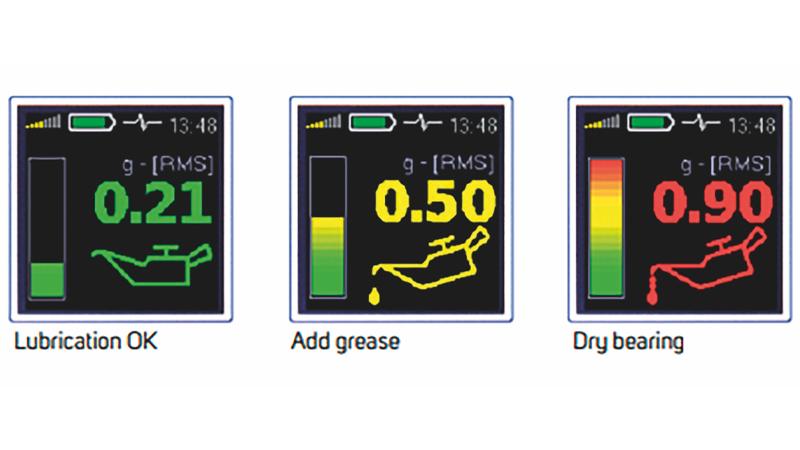

1) Dry bearing – when vibration value is too high, you should increase the grease.

2) Add grease – When the vibration value decreases just slightly, continue to add more grease.

3) Lubrication OK – Once the vibration has decreased to an acceptable level, the bearing is lubricated well.

Lubri can measure and store two basic measurements. Acceleration (in g) for the bearing condition and Velocity (in mm/s) for the whole machine body condition.

Collect the data with Lubri regularly and import them into the free DDS software. Follow vibration trends and observe the actual condition of your machines.

Use the Adash Lubri to extend bearing lifetime and save lubricants. Contact AVO New Zealand for an onsite demonstration today or ask about our wider motor testing solutions.

Key Benefits

- Saves your bearings;

Ensures that your bearing is well greased. - Lubrication optimisation;

Add only necessary amount of grease into a bearing. - Data collector;

Measure, store and trend bearing and whole machine body vibrations.