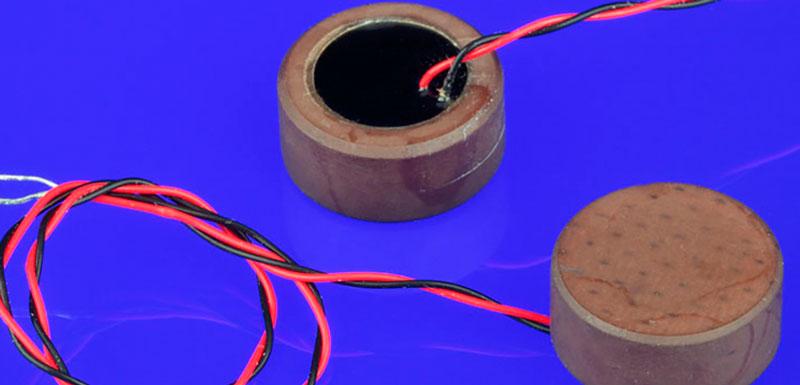

Morgan Advanced Materials has produced a new type of alumina sensor specially designed for high pressure and high temperature water and sub-metering.

The sensor has been specifically developed to withstand extreme temperatures, making it ideally suited to both heat metering and high temperature fluid metering. Manufactured using Morgan’s specially-formulated proprietary alumina, the sensor solves many of the problems associated with high temperature environments, with a focus on reducing thermal drift and zero flow offset over a large temperature range.

The sensor significantly minimises the flow offset because the material has been manufactured to control the thermal properties of both the internal and external structure. This enables the minimum flow rate range to be kept as small as possible, enhancing the overall accuracy of the reading.

The sensor design has been tested up to 100 bar pressure and 150˚C which surpasses the current market requirements for heat metering. This is a direct benefit of using alumina in the sensor design, a material which has minimal expansion properties, and is renowned for its strength and durability.

Due to its thermal stability, the sensor is also excellent for metering of potable water or other fluids, says Morgan. The inert nature of alumina makes a component that is suitable in food and pharmaceutical environments, as well as providing a long operational lifetime.

Morgan also has its own ceramic pressing and injection-moulding capabilities, enabling complete vertical integration from start to finish of the housing and Lead Zirconate Titanate (PZT) elements of the sensor. These in-house capabilities allow Morgan to provide a full design and development package, the company promises.

Company spokesman, Charlie Dowling said the new range of high temperature sensors has undergone extensive research and development to ensure that it is Morgan’s strongest and most effective sensor for use in extreme temperature enviornments. “Available as part of a standard range, or bespoke to order, it promises to reduce environmental factors during metering,” he said.