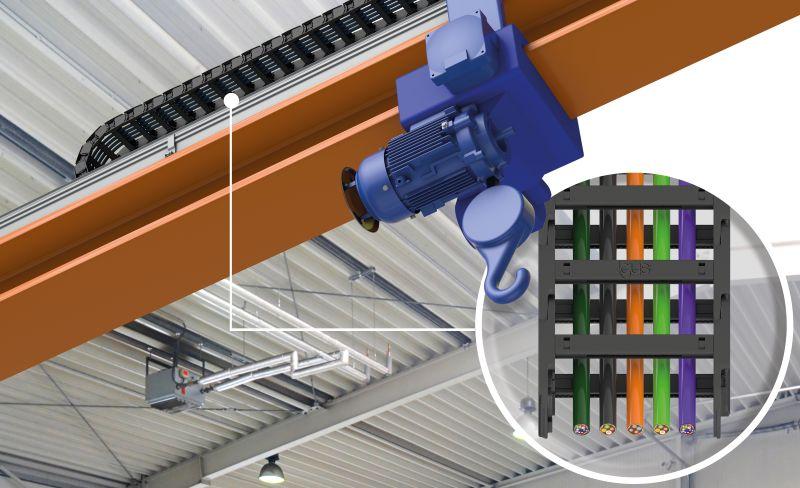

Motion plastics specialist develops a lightweight energy chain for simple gliding applications with long travels

The energy chain specialist igus has developed a product specifically for gliding applications that are ideal for travels of up to 30m, as with indoor cranes. Its slim design ensures cost savings of 30 to 40%.

Energy chains made from high-performance plastics are in use worldwide. They are primarily intended to guide cables reliably, e.g. on indoor cranes used in production halls. igus has now developed a new, particularly cost-effective and lightweight chain, ideal for simple gliding applications with travel distances of up to 30m. The glide-chain G4.42 is characterised by its extra-large sliding surfaces and specific material, which is only used where it is needed for sliding movements. Thanks to this innovative design, the G4.42 is up to 25% lighter than standard igus chains. Another advantage of the G4.42 is the cost-optimised side link used on the left and right. Combined with the large pitch, the glide-chain consists of just a few individual and different components. This results in a price advantage of 30 to 40% compared to standard chains with the same dimensions from igus's E2 and E4 product range. "In times when customers are under massive pressure to reduce their costs, igus has developed a product that not only saves money, but also has a long service life in the application. The new glide-chain was also subjected to intensive test series in the company's own 4,000m2 test laboratory. Furthermore, igus gives a four-year guarantee on all its energy chains.

You can find more information about the glide-chain online at: https://www.igus.eu/energy-chain/news/series-g4-42

Contact:

Treotham Automation Pty Ltd