Low Cost Automation from igus promises obstacle-free entry into the robot era.

Accountants, journalists and even computer scientists are all amazed at how rapidly automation is developing, including with artificial intelligence. Industry representatives are, too. They are drawing new ideas for smart factories. Many traditional SMEs, however, are in danger of falling behind. Low Cost Automation can provide immediate assistance and help them avoid missing the boat.

According to the International Federation of Robotics (IFR), more and more robots are carrying out work in factories. In 2022, the global stock reached a new record of 3.5 million robots, worth an estimated €15.7 billion. Still, the world is a long way from rapid growth, according to a study that McKinsey, a management consultancy firm, recently conducted on the occasion of automatica 2023, a major trade show. In today's manufacturing landscape, the authors see a small number of factories that set automation standards - from artificial intelligence to digital twins to self-learning robots. Artificial intelligence in particular proved to be one of the topics that dominated automatica. The rapid pace of development here heralds a new era of automation. The study indicates that the majority of factories are still a long way from the levels of digitisation and automation that are actually possible today. They risk falling behind in a time of rapid change.

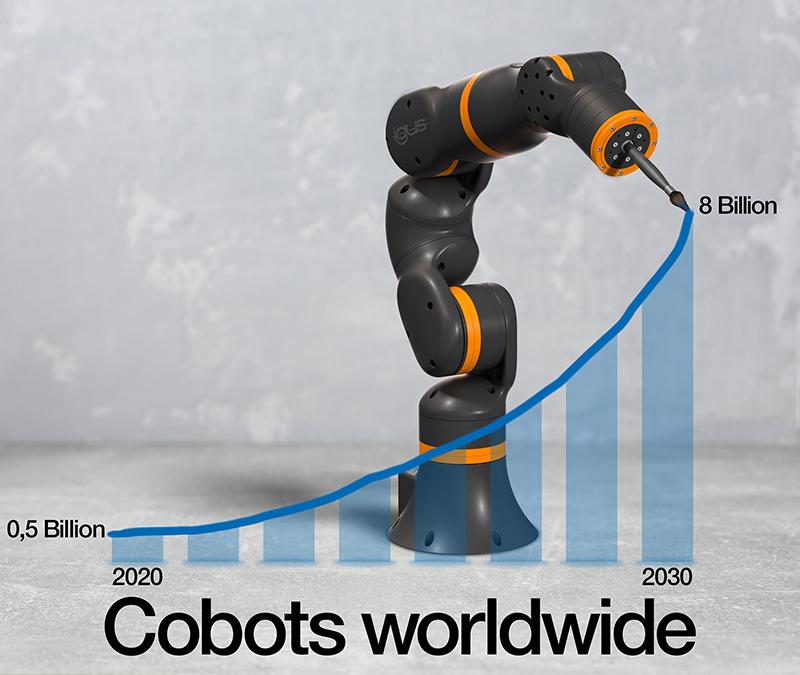

Low Cost Automation is becoming a market segment with great growth potential

RBTX.com: inexpensive robot components from different manufacturers from a single source with price and compatibility guarantees

igus GmbH is one of the providers of Low Cost Automation. To enable SMEs to enter the automation age, the Cologne-based plastics company builds robots at competitive prices. The ReBeL, for example, costs only €4,970 in Germany. The "made in Cologne" cobot is made almost entirely of high-performance plastic and suitable for such applications as loading and unloading machines in industry and serving beer in service. To help interested parties find exactly the right automation solution for their application and budget, igus has created RBTX.com. The online marketplace brings together manufacturers and users of low-cost robotics. Over 100 partners now offer their products here. An online tools allows the combination of robots, machine frames, grippers, conveyor belts etc. and even the testing of movement - very simply with drag and drop in a 3D model on the computer. In future, these functions will also be available in virtual reality. igus has already created its own metaverse for this - the iguverse. No programming knowledge is required.

95% of solutions involve an investment of less than €12,000

"Several thousand SMEs from all over the world have already implemented automation solutions on RBTX.com – from an earthworm farm to a baker who packs doughnuts," says Alexander Mühlens, Head of the Low Cost Automation Business Unit at igus. "95% of the more than 400 solutions involve an investment of less than €12,000. Since the launch of RBTX, we have seen increasing interest. The platform offers more low-cost solutions than any other we know of. We have now provided consultation on over 2,500 projects and sent several thousand robots to the global market. Of course, you have to remember that not every task can be automated with low-cost robotics - especially when very heavy loads need moving or extreme precision is required. However, a wide range of work steps can be automated cost-effectively today. In addition to medium-sized companies, large corporations also use the platform. Every euro saved or quickly amortised counts. The advantage of RBTX is that users get low-cost robotic components from different manufacturers from a single source - and always with a price and compatibility guarantee. Providers have the opportunity to open up new target groups and sales channels for their products. It's a win-win situation for everyone involved." Treotham Automation is the Australian distributor for igus. For more information please contact your nearest Treotham office.

1300 65 75 64