In an exciting world first for SMC Corporation, an innovative portable Compressed Air Leakage Analyser, which does not require ‘host’ machine reprogramming has been designed and built in Australia.

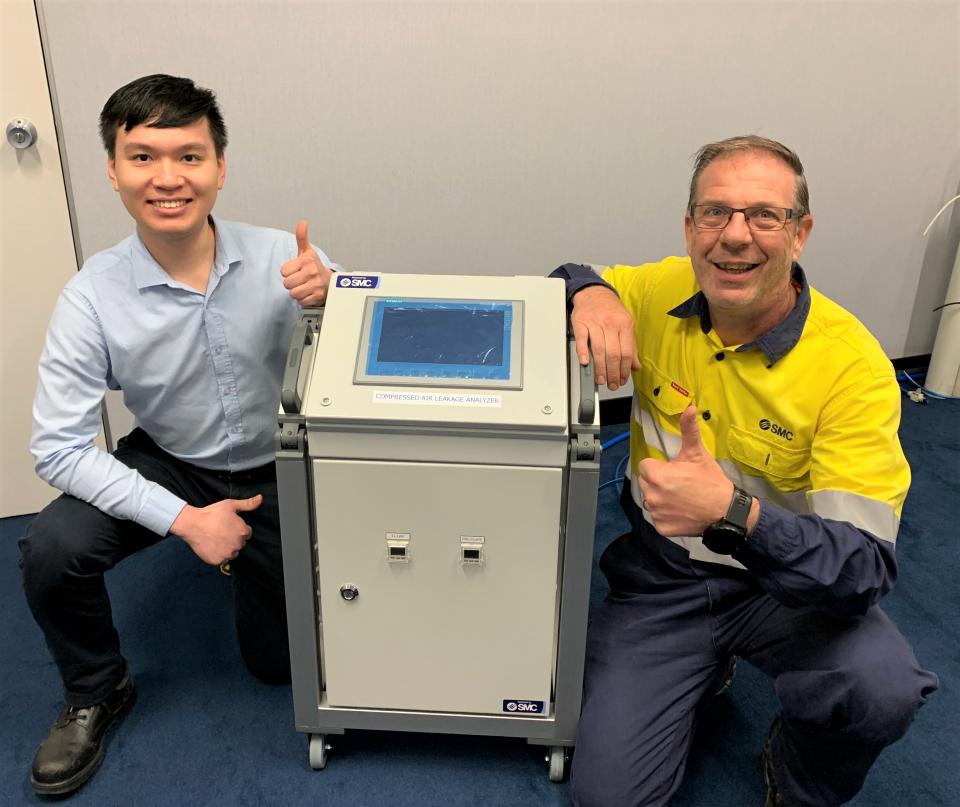

With direction from by Bill Blyth (Energy Conservation Group Manager ANZ), and members of the Sydney based team including Alex Bonella (Project Engineer) and Tim Ho (Mechanical Engineer) SMC Corporation Australia New Zealand’s Energy Conservation Group has commissioned the Compressed Air Leakage Analyzer, which has now been exported to a global food manufacturer in Dubai.

SMC has long focused on reducing the energy costs associated with compressed air applications and with the Global formation of the SMC Energy Conservation Group in 2015 has a team of experts dedicated to developing and integrating technologies to reduce energy usage (and costs) for its customers.

Says Bill: “This latest product development is another example of how SMC helps our customers to realize real energy (cost) savings. Finding and assessing individual leakage in a compressed air system can be costly and time consuming. This state-of-the-art analyzer makes use of a SMC monitoring technology to identify the location and volume for individual leaks; both static and dynamic. A bonus is the ability to also carry out consumption and usage profile analysis for the machine during operation – without the need to reprogram the host machine or process (this is the real time and labour saving aspect). Yet another “SMC maintenance and management tool that helps you make informed decisions about your compressed air management.” this plug-and-play solution can be easily installed and is used to manage and monitor the host machine whilst calculating air consumption for the predetermined pneumatic application.

“This truly is a gamechanger for manufacturers. It allows the machine owners (our customers) to make informed decisions about easily identifying and prioritizing when there is need to repair a leak and what the real value is to your business”, Bill adds. The analyzer will develop and provide a file detailing all measured leaks and other relevant compressed air data and costs – allowing detailed machine maintenance analysis.

The Compressed Air Leakage Analyser is now available for both local and global applications; and can be tailored to suit the many valve control protocols including serial and parallel connected platforms.

Customers who are interested in discussing specific applications or to enquire about a compressed air energy efficiency audit can contact SMC at compressed.air.efficiency@smcanz.com.

Website: www.smcanz.com

For sales enquiries please contact AUsales@smcanz.com or NZsales@smcanz.com