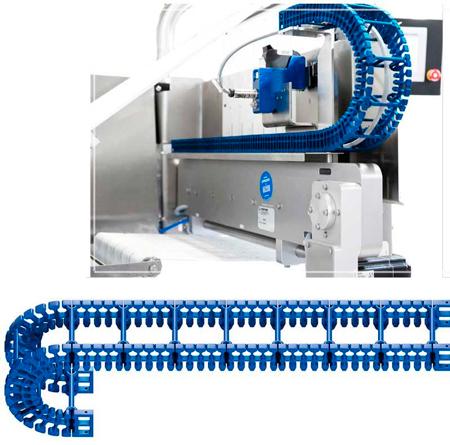

World’s first plastic energy chain according to “Hygienic Design Guidelines”

igus has developed an easy-to-clean energy supply system from FDA-compliant material for the food industry.

For a clean and equally reliable energy supply, the motion plastics specialist igus has developed the first e-chain developed according to “hygienic design guidelines”. Due to the open design, the chain is very easy to clean and, thanks to rounded corners and the absence of threaded connections, dead spaces and therefore resulting germ formation is avoided. The new energy chain is therefore ideally suited for use on machines and systems for the food and packaging industry.

Machine components for the food industry must not only be reliable in operation and avoid product contamination through lubrication-free solutions, they must also be capable of being cleaned easily and quickly. The so-called “Hygienic Design” for the prevention of constructional weak spots on machines is therefore becoming more and more important. For this reason, the motion plastics specialist igus has developed the first e-chain developed according to hygienic design guidelines.

For more information on the TH3 e-chain or any other Igus product, please contact the sales team at Automation Equipment. sales@autoequip.co.nz or 0800 847 200