Reuse energy from compressed air generation: with up to 94 percent recovered energy, BOGE’s screw compressors feature impressive heat recovery components. Users benefit from the heat generated.

Heat recovery means reusing the energy used to generate the compressed air. Instead of being lost as undirected ambient heat, the energy generated is used to heat storage and operating areas or for heating water or oils. Concrete application areas include the treatment of drinking water, service water, heating water and process water. The latter is used for industrial washing processes, for example in recycling companies to clean plastic and synthetic materials as well as in laundrettes. Components can be used to recover heat in both oil-injection cooled and oil-free screw compressors.

Economic efficiency proven in practice

For users, heat recovery is a highly profitable model. Up to 94 percent of the energy used can be recovered. At the same time, the energy for cooling processes within the compressor is reduced as the heat generated is conducted away and used elsewhere. The investment in heat recovery components pays for itself within a few months depending on the application. “The high heating costs are forcing many businesses to save gas. Our experience shows that heat recovery is a highly economical and efficient way of reusing existing energy”, says Frank Hilbrink, product manager at BOGE, in summary.

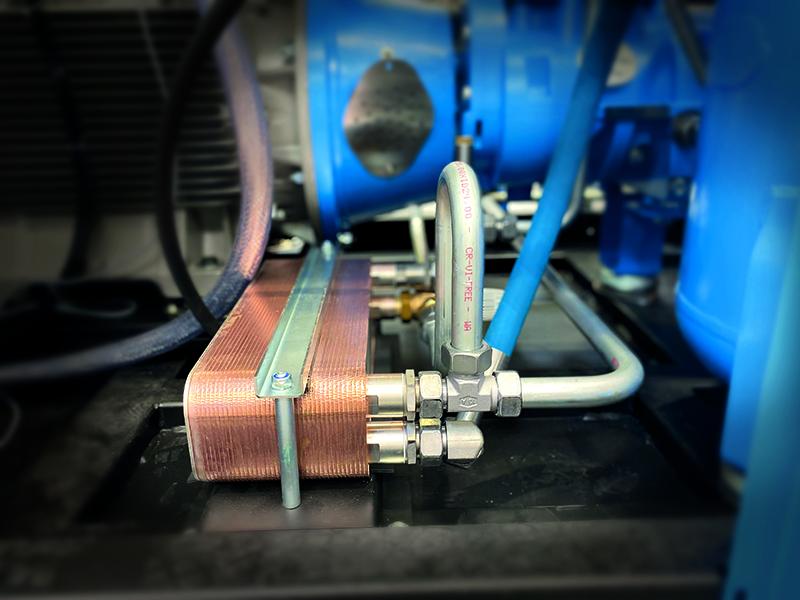

For oil-injection cooled compressors, BOGE offers BOGE Duotherm: an external module for heat recovery in five models for different performance classes. In oil-free compressors, the Bielefeld-based manufacturer customises the process to the respective system. The option of heat recovery is included in all new compressors as standard. Older systems – including those of other manufacturers – can be retrofitted within a day.