Australia and parts of New Zealand face an escalating water crisis, with droughts expected to become more frequent and severe (especially as the weather transitions from La Niña to El Niño conditions). Meanwhile, the growing demand for water is putting local water systems under greater pressure.

According to Martin Broglia, MD of Bonfiglioli Australia and New Zealand, “the local manufacturing and mining sectors, which are responsible for about 20% of all the water consumed, are increasingly seeking out reliable solutions for water and wastewater processes, that will help them mitigate against water scarcity, while also meeting SDG targets”.

Bonfiglio’s portfolio of products and solutions for the water and wastewater sector offers efficient solutions for a variety of applications, including desalination, dewatering, mixing and purification. “Our heavy-duty products meet the complex demands of a range of processes and applications, and are especially effective in handling high radial, axial and torque loads,” adds Broglia.

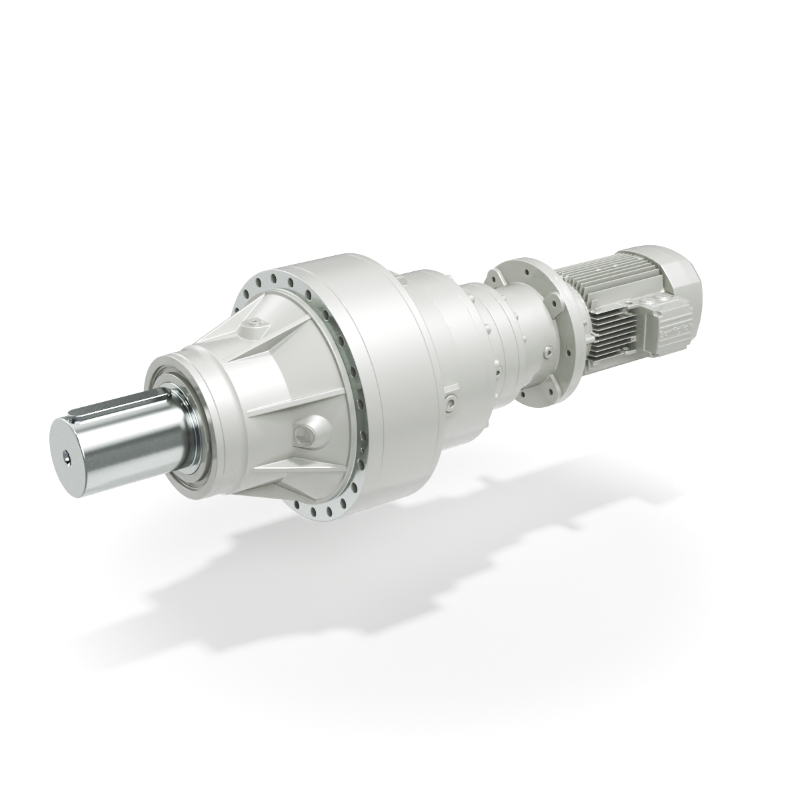

The customisable, flexible and powerful HDP Series parallel shaft gearboxes, HDO Series bevel helical gearboxes and 300 M Series planetary gearboxes offer low maintenance, versatility, and reliability. “By offering reliable speed control and flexibility of transmissible power, these versatile gearboxes enable energy efficient operation of pumps, mixers, aerators, clarifiers, filters and water screens which are key applications in the water industry,” notes Broglia. “Paired with Bonfiglioli’s range of accessories, such as cooling and lubrication solutions, these gearboxes offer extensive functionality.”

Effectively reducing costs

Noting that energy consumption is responsible for about one third of operational costs, Broglia believes that optimising energy use using advanced and integrated mechatronic solutions is key in managing the total cost of ownership (TCO) of installations. “Electronic controls also minimise the stress on electro-mechanical components, resulting in reduced maintenance over time,” says Broglia.

“The integration of our heavy-duty gearboxes with our innovative mechatronic solutions and human machine interfaces (HMIs) enables the automation of water and wastewater treatment processes, driving enhanced efficiency and improved equipment maintenance, while reducing labour requirements,” he elaborates.

Ensuring high quality, fast delivery and maximum uptime

Key to Bonfiglioli’s business strategy is its commitment to international safety and quality standards. The company’s production and assembly plant Quality Systems are TÜV and DNV certified. “Our goal is to develop solutions that enhance system efficiencies, while lowering operating costs,” says Broglia.

Bonfiglioli offers customers large stockholding as well as local assembly and comprehensive support capabilities. In addition, it delivers customised options that extend the useful life of equipment. “Our local team of engineering specialists ensures customers achieve maximum uptime and productivity,” concludes Broglia.