Get on board the journey to the Connected Enterprise for unprecedented productivity gains.

The digital transformation has taken the world by storm and is reshaping the interactions between people, processes and machines. With an estimated 200 billion Internet-connected things by 2030, the digital transformation will transform consumers, industry and governments alike.

The industrial Internet of things is creating a new era for economic growth and competitiveness for industrial companies. Smart manufacturing is the gateway to digital transformation. Connected smart devices open new windows of visibility into processes. Data and analytics enable better and faster decision-making.

Smart operations require the use of new and disruptive technologies, from analytics and mobile to collaborative machines. These technologies communicate with each other and adapt to internal and external conditions. They also require new strategies that make the most of these technologies to create flexible, efficient, responsive and secure operations.

Converged networks

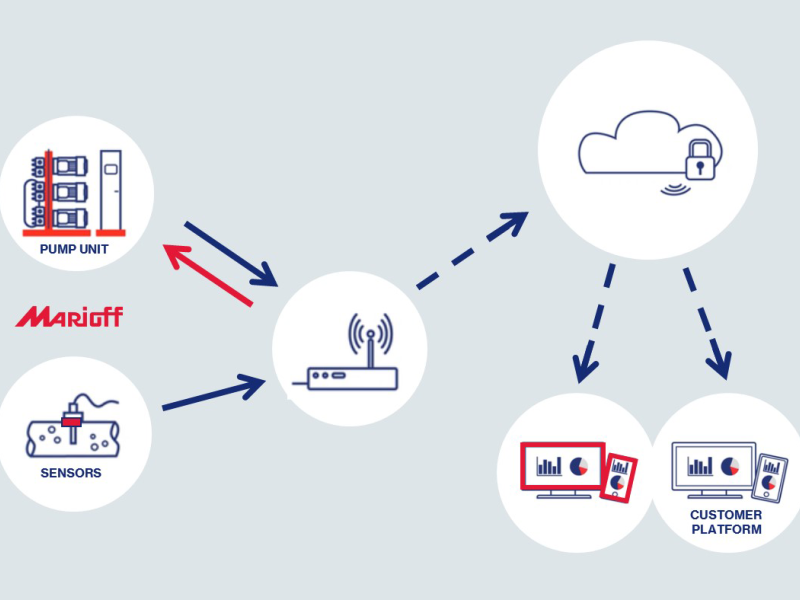

Technologies made possible as a result of the Industrial Internet of Things (IIoT) are already helping forward-thinking manufacturers reap the benefits of Smart Manufacturing. The Connected Enterprise securely connects people, processes, and technologies by converging plant-level and enterprise networks. Implementing the Connected Enterprise is a journey. The first step is to connect to the smart machines and devices that generate data.

In the recent Internet of Things study by the MPI Group, network capabilities to handle the IoT has been named as one of the top five IoT capabilities that present the biggest challenges for manufacturers. However, with the right network infrastructure and the ability to integrate information across IT and control systems, industrial enterprises can coordinate operations and communications – facilitating a demand-driven supply chain.

Converging networks creates a common production platform and new technologies including mobile devices, the cloud, and big data, can help securely connect plant information with enterprise systems.

The Connected Enterprise brings information technology (IT) and operational technology (OT) together into a robust, secure and collaborative architecture. Data is collected that provides operational insights. The next step in the journey is contextualising this data and transforming it into actionable information.

Data and visibility

Technology is transforming industry and unlocking unprecedented quantities of data from intelligent ‘things’ embedded within industrial applications. The days of manually collecting data that may only provide a snapshot in time and are prone to human error are well and truly a thing of the past.

With the proliferation of smart devices and sensors, information is readily available. As bigger data sets are aggregated, businesses get ‘smarter.’ The challenge is contextualizing the data to make it actionable and accessible to all parts of the organisation, maximising efficiency and creating value.

Real-time analytics software takes the data that is automatically and continually collected from several sources and contextualises it into meaningful information. These analytics create greater operational transparency and provides better visibility into complex production processes. This information can provide valuable insights into a number of parameters including quality, safety, compliance, energy-usage and productivity of the plant.

Smart Manufacturing makes the best use of data, contextualising and transforming it into actionable information in real time. It also reconciles historical data to leverage insights in support of future planning. This gives decision-makers across the enterprise new visibility into their operations, as well as the ability to act on business insights, including real-time performance measures and costs.

Productivity gains

In the Connected Enterprise, equipment and devices are transformed into intelligent assets that can self-analyse, predict and adapt to change, providing the ability to monitor processes and equipment in real time to drive out inefficiencies and improve performance.

The result is a more agile, integrated and autonomous operation. With the improved ability to respond to changing customer needs comes better workflow management for more demand driven production, and deeper insight into supplier deliveries that can help improve inventory costs.

The Connected Enterprise enables faster and better business decisions that increase productivity, improve quality and help to meet demand more precisely and cost-effectively through faster time to market, lower total cost of ownership, improved asset utilisation, enterprise risk management and increased workforce efficiency.

A real-life example: Journey to a Connected Enterprise

Being a global manufacturer, Rockwell Automation recently embarked on their own journey to the Connected Enterprise. Similar to other manufacturers with large product portfolios and a global manufacturing presence, Rockwell Automation used a range of manufacturing processes at its 20 different plants. Each plant ran its systems, with none of them talking to each other.

The company developed a five-year plan for the complete restructuring of their facility and supplier networks. Rockwell Automation started the journey by establishing a single connected system across the globe utilising Ethernet/IP. In tandem, they rolled out a new, unified ERP and MES solutions across all of the production sites. The company has experienced an estimated 4-5% annual improvement in productivity.

The Industrial Internet of Things era has arrived. This proliferation of connected smart devices can improve virtually every aspect of business performance with leading organisations taking advantage of its many benefits.