By Matt Hale, International Sales & Marketing Director, HRS Heat Exchangers

Heat exchangers often play an important role in wastewater treatment systems but given the nature of wastewater streams and the processes involved, including evaporation and anaerobic digestion, it is important that the right technologies are selected to maximise process and energy efficiency.

There are a number of applications for heat exchangers in wastewater treatment. They can be used to recover heat from raw or treated sewage, to preheat sludge prior to anaerobic digestion, or to remove water from wastes and sludges through evaporation. Pasteurisation of waste streams may be required to meet environmental rules, or water or effluent may need cooling before it is discharged to the environment in order to meet local legislation. Each process will place different demands on the heat exchanger being used, and some processes may be combined (e.g., recovering heat from treated sludge and using it to pre-heat untreated sludge before digestion).

The basic practical considerations when choosing a heat exchanger for wastewater treatment are the same as for any other application, and include factors such as the physical space available, the available temperature of the product and process materials and the required temperatures after processing, acceptable pressure drop and the service materials being employed. However, there are also other considerations which while not unique, are particularly relevant to wastewater and sludges. These include the physical nature of the material and the potential for fouling in the heat exchanger, ease of maintenance and the ability to operate reliably for long periods of time. Finally general considerations include energy efficiency, capital and operating costs are also crucial to the final choice of heat exchanger. The total cost of ownership should be considered, as units that are cheap to purchase often have higher running costs or lower operational efficiencies.

Obviously, the biggest factor when choosing a heat exchanger is the nature of the material itself. Some wastewater streams will be relatively clean, containing only a few dissolved chemicals, while others will be a mixture of dissolved and suspended materials. At the other extreme, the thickest most viscous semi-solid sludges will need significant power to move them through the exchanger, and the risks of fouling and the importance of the pressure drop will therefore be much greater.

Several types of exchanger are utilised in wastewater treatment with differing levels of success, according to the type, the actual design of individual units, and the processes they are used for. In essence the four types of heat exchanger encountered in wastewater treatment are: spiral heat exchangers; plate heat exchangers; tubular heat exchangers; and scraped surface heat exchangers.

Spiral heat exchangers (SHEs), which are sometimes known as shell and coil heat exchangers, are almost uniquely used in wastewater and sludge applications. They consist of a single channel formed into a spiral or coil, creating a compact design. Various options such as wider spacing and the removal of baffles are employed to try to reduce fouling and the design’s large surface area and true counter-current flow results in high thermal efficiency. However, they require regular cleaning (which is both time consuming and costly) and are often unsuitable for sludge-to-sludge heat transfer.

Plate heat exchangers (PHEs) are one of the most common types of heat exchanger and they have a compact design with good thermal efficiency. However, they are highly prone to fouling and are often only suitable for relatively clean, non-viscous materials. Their maintenance schedules also often require regular replacement of the bespoke gaskets that separate the plates.

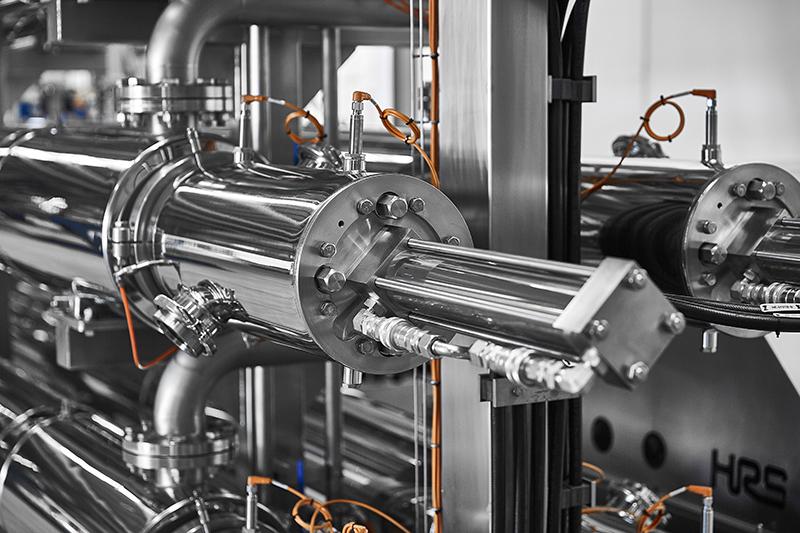

Tubular heat exchangers, also known as shell and tube, comprise a tube or tubes within another tube or vessel. Because of the various designs and geometries available, they are better able to cope with more viscous materials and suspended solids. Depending on their design, they can require more space than some other designs, and can be susceptible to fouling. These issues are greatly reduced by using corrugated tube designs, and HRS produces a range of efficient and cost-effective corrugated tube heat exchangers for wastewater and environmental use, depending on the viscosity and physical characteristics of the product. These include the DTI and DTR Series of Double Tube designs for more viscous products, and the C & K Series of Multi-Tube designs for lower viscosity fluids which may contain small particles.

Scraped surface heat exchangers (SSHEs) are used where materials are very viscous or have a high fouling potential, so they are particularly suited for treating thick sludges and for use in evaporation systems. The use of a scraper keeps the tube surface clean and maintains high thermal efficiency, while the individual design may provide other benefits, such as controlling product viscosity during processing. HRS offer two different types of scraped surface heat exchanger, but the most suitable for wastewater applications is the patented Unicus Series uses a reciprocating action with a choice of scraper geometries, making it ideal for applications such as effluent evaporation, where fouling or low heat transfer is a problem.