Reuters reports that nearly half of global consumers purchased more fresh, unprocessed foods over the past year. Today’s consumers are not only checking ingredient lists, they’re scrutinising how food is made — and 75 per cent say they’re willing to pay more for clean-label products, according to NielsenIQ. These shifting expectations mean food manufacturers must adapt not only their formulations, but their equipment too. Here, Chris Johnson, managing director at SMB Bearings, explains why the smallest components, like industrial bearings, are playing a bigger role in food safety and compliance.

The same Reuters article found that, as of March 2025, 30 per cent of global food and beverage launches featured a clean label claim in the past year. The clean-label movement — built on transparency, traceability and minimal processing — is accelerating demand for hygienically engineered machinery and manufacturing processes.

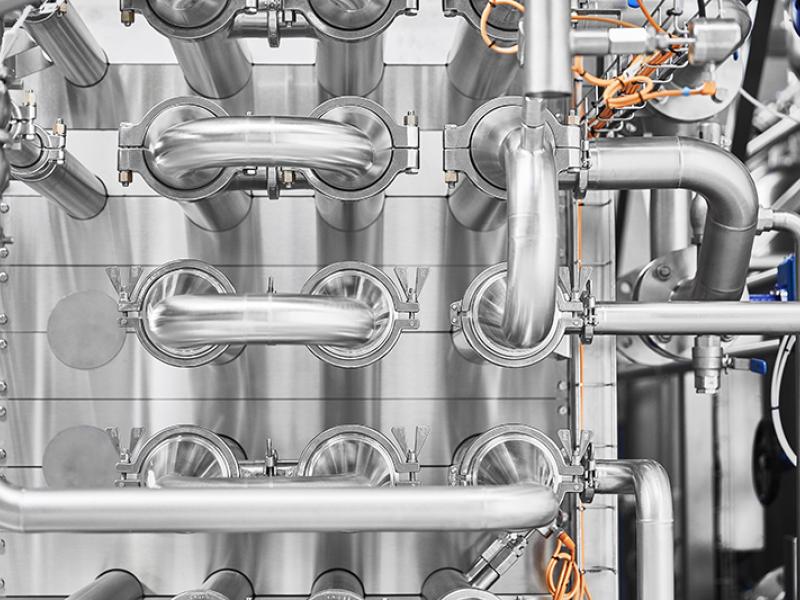

For manufacturers, this means re-evaluating the materials and maintenance requirements of every part of their equipment, which brings us to bearings. These often-invisible components are critical to food processing equipment, from rotary slicers and conveyor systems to packaging and mixing machines. But as the sector evolves, bearings must now meet much more than performance metrics.

In clean-label facilities, for example, they must resist corrosion, endure aggressive washdowns and eliminate contamination risk — all while complying with food safety standards like European Union Regulation (EC) No 1935/2004 and the United States Food and Drug Administration (FDA)’s FDA CFR Title 21.

However, traditional bearings often fall short under these demands, which is why manufacturers must embrace alternatives.

Stainless steel and hybrid bearings

Manufacturers are shifting to stainless steel bearings or hybrid bearings with sealed, lubricated-for-life designs. These options are not only mechanically robust but are easier to sanitise and less likely to introduce contaminants.

Stainless steel and hybrid bearings are particularly well-suited to food and beverage environments because of their superior corrosion resistance, mechanical strength and cleanability. Stainless steel offers high resistance to rust and chemical damage, making it ideal for machinery that must endure daily washdowns with caustic or chlorinated cleaning agents.

Hybrid bearings, with stainless steel races and ceramic balls, offer superior wear resistance, lower friction, and enhanced reliability in harsh conditions. Their sealed, lubricated-for-life design reduces maintenance and downtime — a key advantage in food production, where bearing failure can disrupt operations and risk contamination. By choosing stainless steel or hybrid options, manufacturers not only meet strict hygiene standards but also safeguard production uptime and product integrity.

Lubrication for bearings is another critical part of the equation, as leaking or degrading grease can contaminate food. To mitigate this risk, food-safe lubricants compliant with UK Food Safety Act 1990 or National Sanitation Foundation (NSF) H1 or H3 standards in the US are now a baseline requirement. Solid or lifetime lubrication is increasingly specified, especially in allergen-free or vegan facilities where even minor cross-contact can trigger costly recalls.

Take a salad processing line. Equipment here faces water, vibration and sanitising chemicals — often several times a day. Bearings in these environments must be sealed against ingress, made from corrosion-resistant materials, and pre-lubricated with food-grade grease that won’t degrade under pressure. Bearings that meet these standards don’t just protect consumers, they reduce downtime, extend service life and support compliance with regulations and retailer audit schemes.

Greater transparency

Hygiene is just one piece of the puzzle. Traceability is now a central requirement too. Food processors must demonstrate full component traceability, especially when supplying large retailers or exporting internationally. That means knowing where each bearing came from, what materials it’s made of, and how it meets relevant safety standards.

That’s why specialty bearing suppliers like SMB Bearings offer stainless steel and hybrid units designed for food and beverage use — complete with food-safe lubricants and compliance documentation. Cost-conscious manufacturers may wonder about the return on investment (ROI) of upgrading to food-safe bearing systems, but benefits like reduced downtime, fewer recalls, and extended maintenance intervals often far outweigh the initial cost.

As consumers demand greater transparency and cleaner labels, food manufacturers must respond with more than just new recipes — they need smarter, safer machinery built for compliance and hygiene. Bearings may be small, but their impact on food safety, equipment reliability and regulatory compliance is significant. Stainless steel and hybrid designs with food-safe lubrication are no longer optional upgrades — they’re essential components of a clean-label strategy.

To explore how hygienic, food-grade bearings can support clean-label and compliance