Protection of process solutions and particularly water storage is more important than ever, through increasing wet and dry cycles. This summer is forecast to produce more rain in many areas (www.bom.gov.au/climate/outlooks/#/overview/summary)

As Australia looks forward to the prospect of a wetter-than-usual summer in many parts of the country, many public utilities and private industries are preparing to harvest and safeguard water to safeguard against drier times in the future.

“Open storage tanks are obviously one area of concern, inviting evaporation and airborne pollution of both a chemical nature and from flourishing birdlife. With climate change, water is becoming too valuable to waste,” says Laurie Green, Managing Director of Cut To Size Plastics.

Mr Green, who has seen tank design evolve over decades as a leader in tough engineered non-polluting and also food grade plastics, both manufactures long-life tanks and, through his subsidiary Hercules Engineering, helps develop tank top bearings to help protect their contents.

He says storage tanks today can hold upwards of 10, 20 or even 30,000 tons of liquid that must be protected from the elements and from pollution to safeguard it for use in water, wastewater, emergency fire protection and high purity industrial processing applications.

“Not only are tanks being built to hold their contents more safely and securely than ever before, as awareness rises about water wastage and product purity, but also they are expected to do it for longer and in more challenging and generally warmer environments. Steel, concrete and fibreglass tanks need secure roofs that can withstand expansion and contraction caused by factors such as increasing climatic and load variations” says Mr Green, whose subsidiary company, complements Cut To Size’s tank construction with sliding roof bearing to account for thermal expansion and contraction and structural load variations.

HDPE tanks from Cut To Size are manufactured from the most environmentally stable of all engineering plastics

Cut To Size manufactures light and strong long-life high density polyethylene tanks, available in capacities of more than 25,000 litres for potable water and a wide variety of chemical solutions used in food, beverage and industrial process applications.

HDPE plastic is one of the most environmentally stable plastics, giving off no harmful fumes into the environment, nor will it absorb disease, odour or moisture. The tough, lightweight product is easy to transport and position, swift and safe to erect and has extremely good lifespans, being identical in formulation to PE100 piping material that has proven its durability over many decades in inside, outside and underground uses.

“Over the years many larger chemical process tanks have been constructed from fibreglass supported by steel frames. PE100 tanks don’t require framework of any kind, and need liners only for the most aggressive chemicals, such as sodium hypochlorite,” says Mr Green.

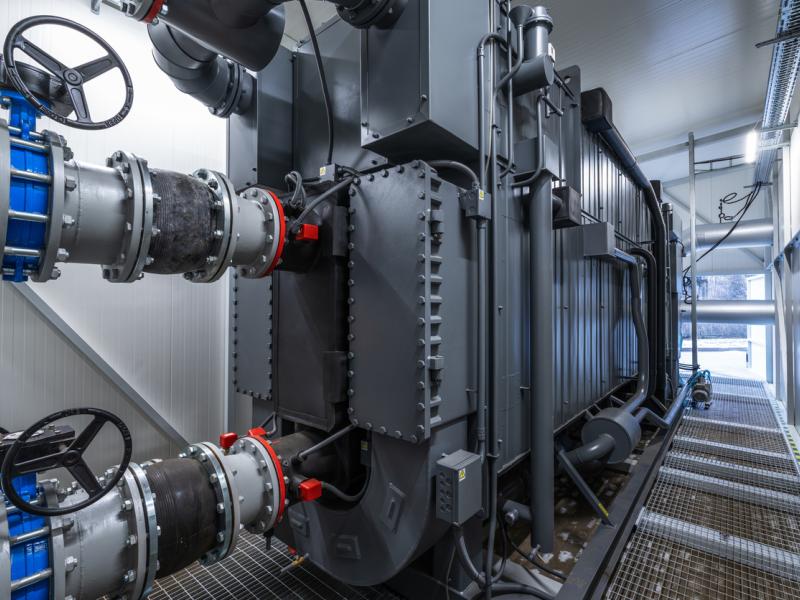

Hercules sliding bearings for tanks

Hercules Engineering, meanwhile, produces sliding bearings that address challenges facing developers and operators of buildings and processing plants for industrial and municipal uses. These purpose-designed tank bearings ensure their top structures can flexibly cope with internal movement from climatically induced expansion, contraction and wind and rain forces, while also coping with production stresses caused by heavy and changing loads, vibration and other factors encountered within diverse industries. Relevant industries can include mining and energy, oil and gas, ports and infrastructure, food and beverage, primary processing, manufacturing, materials handling, water and wastewater utility and emergency services.

The cost-efficient solution to many such issues offered by Hercules Engineering through its range of Herculon Type D Tank Top Bearings (HLD/TT) Bearings, which are engineered for easy installation under roof beams of tank tops and other lighter structures including some building roofs. These low-friction easy-slip bearings are particularly useful where loads are relatively small but both lateral and uplift forces need to be accommodated, says Mr David Booty, Manager, Hercules Engineering.

“Light but strong and flexible tank tops are now widely employed to protect tanks and their contents from external pollution ranging from flora, fauna, dust and droppings and water-borne impurity. The bearings used under these tops must not only support the structure, but also prevent it from cracking and breaking and becoming part of the pollution problem.”

HLD/TT bearings are part of a proven range of Hercules composite slip joints and structural bearings for a wide variety of structures and weights incorporating engineered high-performance combinations of engineered composite polymer materials and metal facing surfaces. Complementary Type D Herculon Bearings HLD/SG are designed to accept a lateral load of 30 per cent of the vertical rated load, which can be up to 600 kN per bearing in stock sizes, with higher capacity available custom-engineered for particular applications.

HLD/TT bearings consist of a thin stainless-steel slide plate with two stainless steel studs flash welded to the upper face. The lower face is highly polished, and the plate is provided with two slotted holes for uplift through-bolts. This plate slides against a PTFE- coated Hercupad, which has two clearance holes drilled into it. Features include:

Construction and performance characteristics

• Five stock sizes in working loads from 50-70 kN. Larger capacities and different dimensions can be custom engineered.

• Co-efficient of friction 0.05- 0.08, depending on stress

• Expansion capacity up to ± 20mm (can be custom designed for larger movements)

• Maximum rotation up to 0.01 radians

• Maximum temperature 80 deg C

Laurie Green says his company’s move into water storage and protection has been promoted by expanding long-term demand about ways to most efficiently conserve water and liquids.

“Australasia is still relatively early in its water conservation journey, but this will be an issue of rising importance over the years ahead. Water harvest and water conservation will quickly become not only a national priority, but also a big issue for individual private and public entities.”

For further information, please contact Cut To Size Plastics Pty Ltd by calling 1800 CUT2SIZE, or contacting our offices: