The "Hydrothermal Plastic Recycling Solution" of startup Mura Technology promises the conversion of plastic back to oil in just 25 minutes. In order for entry into a sustainable circular economy to succeed, globally active industrial companies such as igus are supporting the development of this technology. Dow Chemical, the world's second largest chemical company, is now another partner on board.

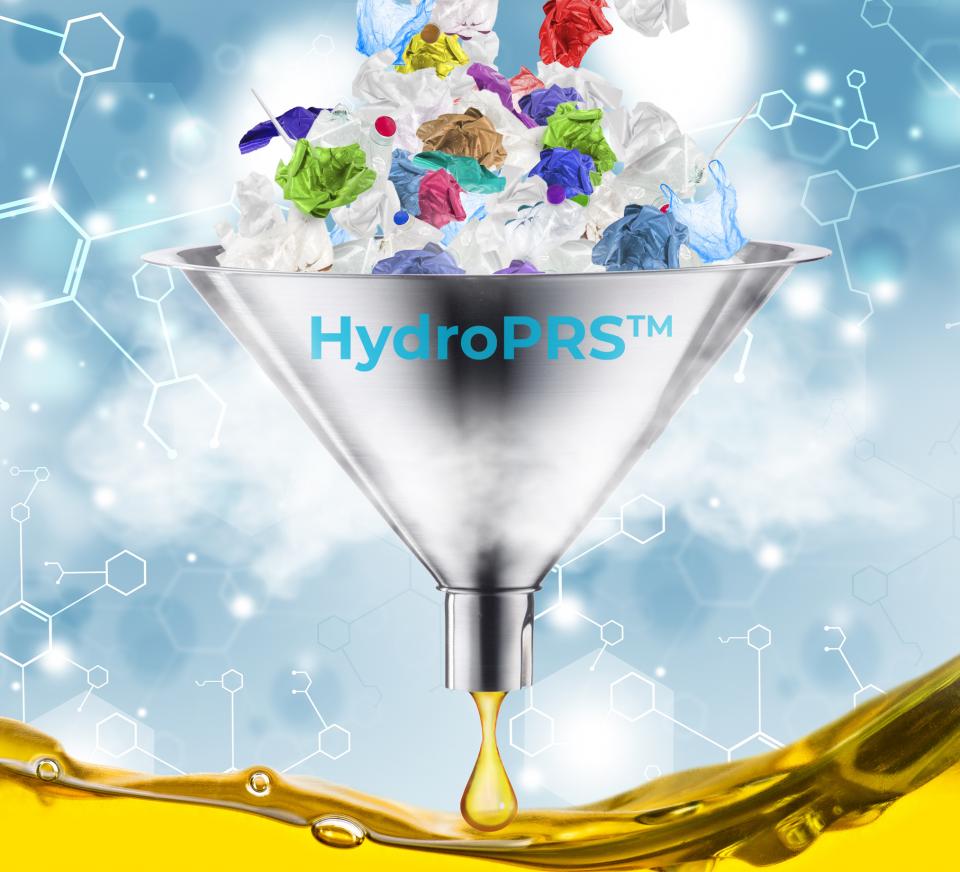

With the "Hydrothermal Plastic Recycling Solution" (HydroPRS), Mura Technology has developed a novel technology for chemical plastic recycling. The aim is to build a sustainable circular economy for plastics and prevent plastic waste from entering the environment. The method uses water, heat and pressure to convert plastic waste back into oil in just 25 minutes. The startup Mura Technology has already entered into collaborations with the engineering services company KBR and the motion plastics specialist igus. igus was the first investor from the industrial sector at the end of 2019 and had further increased its investment to 5 million euros in March. Now, Dow Chemical, a global developer and producer of plastics, is joining as another major partner. The collaboration will further drive the scaling of Mura's advanced recycling process.

Plastic waste becomes new packaging

The world's first facility to use HydroPRS on a large scale is currently being built in Teesside, UK. The first line with a capacity of 20,000 tonnes per year is expected to start operation in 2022. Once all four lines are completed, Mura will be able to recycle up to 80,000 tonnes of plastic waste per year and supply Dow with the raw materials obtained through the process. Dow will use this to develop new plastics for food packaging and other packaging products that will eventually be returned into global supply chains. Dow's commitment is also intended to demonstrate that Mura's solution can meet both the sustainability and performance requirements of the industry and that products made with HydroPRS can be used on a large scale to produce new plastics. igus CEO Frank Blase also welcomes the collaboration: "Strong partnerships are needed to help this technology achieve a breakthrough and thereby create a noticeable effect for the environment. We are delighted for Mura that Dow is on board."

Contact:

0800 847 200