Forklift operators who are insufficiently aware of the load they are lifting and the risks that come with exceeding the forklift rated capacity not only compromise their own safety, but also place everyone working around them at serious risk.

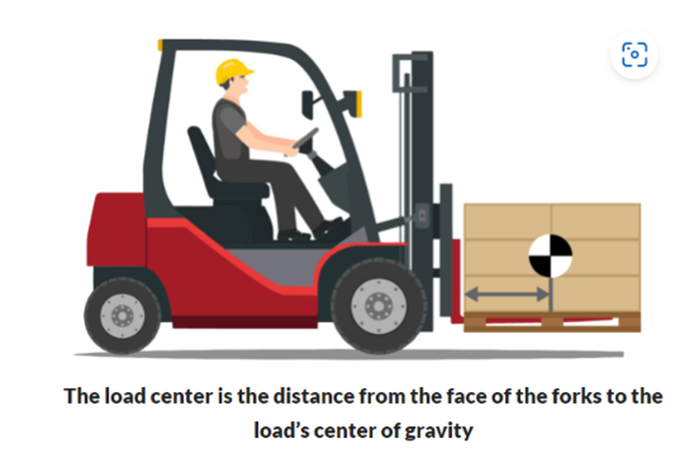

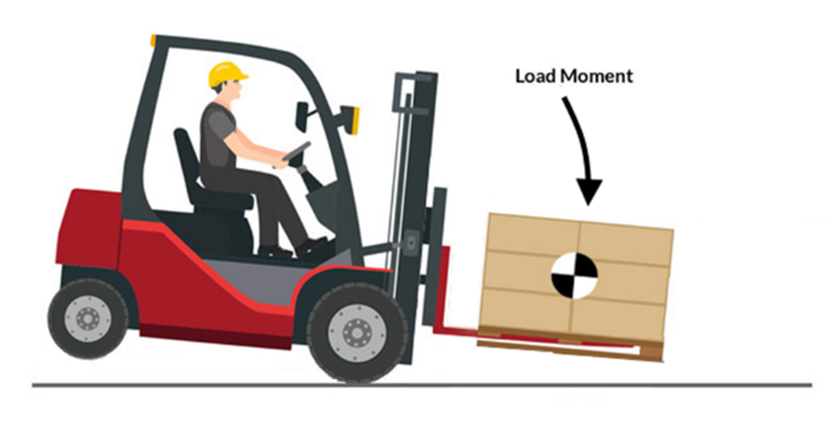

There are several factors that can influence a forklift truck to become overloaded and these include: load centre, weight of load, lift height and the type of load. The load centre, which is the distance from the face of fork to the centre of gravity of the load plays a crucial part. The position of the load centre can also vary depending on the type of load being lifted, for example liquid loads or non-uniform loads.

Forklift operators should be competent in understanding the weight of the load. Combilift’s new product, the Combi Safe-Lift, is an anti-overload device which enables operators to avoid the pitfalls of potential overloading, which can have serious consequences if it occurs.

The Combi Safe-Lift incorporates a strain sensor on the mast section (See Pic.) and a lift cut-out valve on the hydraulic line to disable lifting if the unit is being potentially overloaded.

There is an audible alarm which warns the operator of an overload situation and a load moment indicator is fitted to the dashboard in the cab. The operator can instantly see from the green, amber and red “traffic light” signalling when there is a risk of overloading or when the forks are not fully engaged for example, and take appropriate action.

MD Martin McVicar: “We offer the Combi Safe-Lift as an option at the moment but we believe that this simple and cost-effective system should become a standard option on all counterbalance trucks in future. Fitting a straightforward device such as the Combi Safe-Lift is an effective way to reduce risks for the operator and other personnel, and also to avoid product damage as well as costly repairs.”