AQUAVISTA Plant, is a holistic digital solution composed of a suite of intelligent software solutions for real-time optimisation of process performance, says Veolia Water Technologies. It provides a state-of-the-art auto-pilot to optimize the whole wastewater system, including sewer network and treatment plant. Aquavista Plant focuses on real-time automated optimisation of the consumption of energy and chemicals, biological and hydraulic capacity enhancement, stable operation and compliance of wastewater treatment plants and sewer networks. It is suitable for small and large municipal and industrial wastewater treatment plants, says the water technologies company.

The company states that Aquavista Plant reinforces its position as the leading supplier of flexible, scalable and agile real-time features for all types of water treatment, achieved through:

• Development of intelligent, adaptive and self-learning features which lead to an increase in safety and reliability while helping to mitigate water challenges.

• Design of features that provide valuable information and set-points from a minimum of on-line instrumentation.

• Supply of intuitive user interfaces and fast implementation of solutions providing high customer satisfaction.

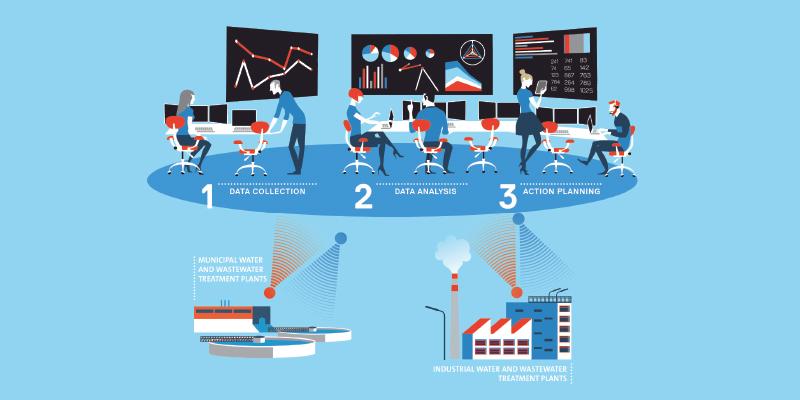

More than 50 features are available today, from activated sludge, Biofilter, MBBR, UASB and physical/chemical processes to anaerobic digesters, anammox processes and sewer networks, making it the most comprehensive digital offer for the water industry, says Veolia. Depending on the number of installed features, Aquavista Plant analyses several sensor measurements in real time and, based on a holistic analysis across all the data collected, it will make optimised set-points available in real time, 24/7 for all parts of the wastewater treatment plant and/or the sewer network. With combined optimisation, the wastewater treatment plant and the sewer network can perform as one integrated treatment system, for the maximum benefit of the environment and the treatment costs.

Chief Digital Officer Aude Giard, said when a client subscribes to the Aquavista Plant service, [they are] invited to preselect a number of features: real-time optimisation, overview, forecast features as well as a number of dedicated characteristics, which all operate in real time.

“The operator will still be in control of the operation since he is the one who defines the strategy according to what Aquavista Plant has to optimise: best possible effluent, lowest cost, highest level of security for compliance, etc., she says. “The benefits for our clients are numerous, from OPEX savings to increase of the biological and hydraulic capacity of the treatment plant, which will save CAPEX for extensions and upgrades, to stable operation and compliance.”

Aquavista Plant is currently implemented across several countries with hundreds of wastewater treatment plants already connected and benefiting from 20-50 percent in overall OPEX savings, up to 40 percent more biological and up to 100 percent more hydraulic capacity, improved effluent quality at the wastewater treatment plant as well as a reduction of combined sewer overflows (CSOs).

BlueKolding, a Danish utility company covering the city of Kolding and its suburbs, installed Aquavista Plant at all four wastewater treatment plants and the sewer network. AQUAVISTA Plant has ensured BlueKolding 40 percent savings in operating costs, 25 percent improved effluent quality, and 80 percent increased hydraulic capacity that leads to more than 67 percent reductions in CSOs with a 22 percent reduction in capital investment for retention basins.

“As a manager of a utility, Aquavista Plant lets me know what we get for our money and how we are performing. Aquavista Plant helps us to lower the costs of our operations and helps us to have a better carbon footprint as well. The fact that it is a cloud-based solution means that our data security is on a very high level and that’s very important to us,”says Per Holm, CEO of BlueKolding.

AQUAVISTA Plant is designed with the maximum security

Data security is ensured according to the Aquavista Digital Platform security practices, covering various levels of data management. Cloud security is ensured by secure communication through encryption and certificates, role-based user access, and strictly one-way communication from the plant to the cloud. Cybersecurity compliance is guaranteed by standard protocols and industry-proven security architecture practices.