What was once simply a dream is now becoming reality: new products and services in the compressed air production sector are bringing Industry 4.0 to life, says Kaeser.

Many believe that we are now entering the fourth industrial revolution – Industry 4.0 – where manufacturing is led by cyber-physical systems.

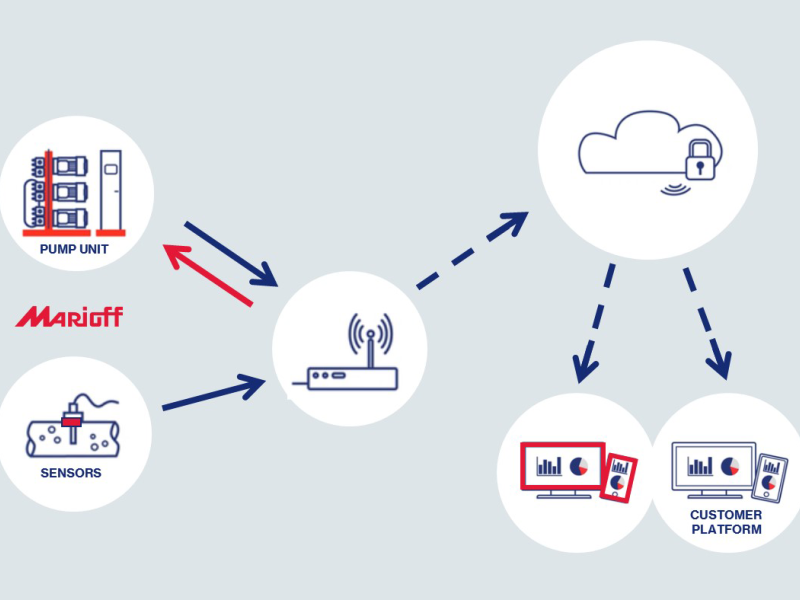

Cyber-physical systems normally comprise of computers, networks and physical processes all integrated together. Sending information back and forth, the computers and networks monitor and control the physical processes, with feedback from the physical processes also impacting the subsequent computations.

Using cyber-physical systems allows manufacturers to merge the physical world with the virtual world and is sometimes called the Internet of Things (IoT).

Welcome to Industry 4.0

When it comes to compressed air production, intelligent contracting model-based solutions, such as Sigma Air Utility, have been available for quite some time. Combining highly efficient, innovative products with intelligent engineering and predictive maintenance services, has in essence laid the foundation for Industry 4.0 in the compressed air production sector. Now, thanks to new communications technologies and services, such compressed air contracting models are being further refined and improved.

These solutions not only include the components of the compressed air station itself but also the many services rendered throughout its lifecycle such as optimal compressed air supply system design and regular maintenance, not to mention energy management, the planning of new systems and expansion of existing ones.

To take full advantage of their Industry 4.0 capabilities, components must support efficient control in combination with other machines and provide real-time operating data for monitoring purposes, as well as being able to forward all relevant data to master control systems.

Modern compressors and compressed air treatment components are therefore equipped with internal controllers based on industrial PC technology which are able to pass data to a master control system via interfaces such as Ethernet. The data generated by the components are first delivered to a master controller, such as the Sigma Air Manager 4.0 (SAM 4.0).

This controller acts as an actual management system for the compressed air station as well as a central node for the forwarding of relevant data.

Advanced management systems must meet demanding challenges. They must be capable of efficient and predictive compressor control, taking into account a range of contributing factors, such as switching and control losses. They must also be able to handle the volume of incoming data from the compressor station, compiling it appropriately and sending it on to a superordinate service centre.

Multiple levels of functionality

These advanced controllers allow for varying levels of involvement by external service providers so operators can choose to perform the evaluation and servicing of the system themselves. In this case, the master controller is integrated into the operator’s control system.

Alternatively, operators can opt for a conventional service agreement. Or, in order to take advantage of further services, they can choose a predictive maintenance service model, and then there’s the option of remote diagnostics. Real-time monitoring of a full range of sensor data enables immediate response to unusual operating statuses and lays the foundation for optimal service planning. Thanks to intelligent predictive tools, operators will already know what’s going to occur in the compressed air station.

Such advanced solutions represent the highest level of operational reliability and offer some key advantages; operators are released from the burden of performing maintenance and service on the compressed air station, outsourcing allows customers to benefit from the very latest knowledge and expertise in the compressed air technology sector and it delivers clear-cut cost advantages. Moreover, real-time monitoring gives the service provider a detailed picture of what is happening in the compressed air station and peripheral equipment.

Always up to date

If irregularities occur, a notification is automatically sent to the service provider; this then triggers preventative measures. Sophisticated algorithms further allow specialists to predictively estimate whether potential disruptions may occur in the near future and if so, to take appropriate preventative measures.

Such needs-based maintenance cuts costs and prevents system failures. Operators enjoy significantly enhanced reliability, cost-optimised servicing, longer system service life and assured specific power. However, the benefits extend far beyond the guaranteed high availability of their compressed air systems. Lifecycle costs can be reduced by up to 30 percent as the specialist can adjust the energy performance of the compressed air station according to demand.

And, the usefulness of the data does not end there! Through analysis of how products behave during disruptions the service provider is able to identify patterns and causes of malfunctions in order to ultimately develop and optimise the components and further enhance operational reliability in the future.

Engineering

Base: the ideal planning tool

To take full advantage of a compressed air system’s Industry 4.0 capabilities another key service is required: proper planning. This involves gathering all the parameters and components relevant for compressed air production in a planning tool, such as Engineering Base, which allows operators to systematically track every aspect of their compressed air system throughout its entire lifecycle. This also ultimately serves as the foundation for intelligent services such as predictive maintenance.

Engineering Base is a powerful tool that records and maintains data, storing it securely and ensuring it is always up to date thanks to real-time transmission and evaluation.

In terms of planning new systems, it elevates optimal design of the compressed air station to a new level. The data is also an ideal resource when optimisation measures are to be implemented and it saves time when it comes to expanding or reconfiguring the system.

Conclusion

Operators that choose to take advantage of Industry 4.0 compressed air technology solutions will enjoy highly efficient components and all of the benefits of precision planning. Yet the whole package is far greater than the sum of its parts: a state-of-the-art system in terms of energy efficiency; which in turn translates into the most significant reductions in energy costs; not to mention innovative services like predictive maintenance, which reduce other service costs throughout the system’s entire lifecycle.