For the different types of bulk materials, Nord Drivesystems offers suitable drives for belt conveyors, bucket elevators and other transport systems.

Whether sand, coal or food such as grain or sugar – a quite considerable share of the goods transported on road, water and rail is bulk material. This wide range of different materials shows how diverse the requirements for drive systems are when transporting bulk goods.

“Our Industry Sector Management has extensive knowledge of bulk handling and is well acquainted with the industry's requirements”, explains Jörg Niermann, Head of Marketing at NORD. The drive specialist offers customised drive systems for transport systems such as belt conveyors, bucket elevators and screw conveyors. “Our portfolio comprises highly robust systems for applications in harsh environmental conditions, as well as explosion-protected and particularly hygienic drive systems.”

Comprehensive modular system

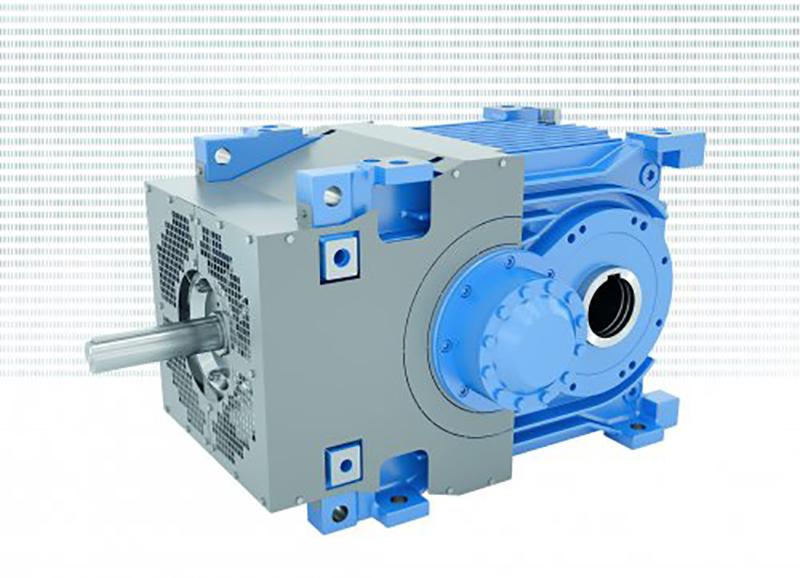

In order to tailor systems for all applications, the industry experts use the comprehensive NORD modular system. It comprises components such as frequency inverters, motors, gear units, couplings and brakes as well as fans, base frames and back stops, which are individually matched. For many applications, the basis is a gear unit from the MAXXDRIVE industrial gear unit series. These gear units, which are principally installed in one-piece UNICASE housings, are available in eleven sizes with torques of up to 282,000 Nm.

For the bulk material industry, NORD developed the MAXXDRIVE XT industrial gear unit. The power and speed ranges of the application-optimised two-stage right-angle gear units have been designed for applications requiring low speed ratios in combination with high powers. Its robust design makes the MAXXDRIVE XT resistant to dirt and reliable in rough operating conditions. A special sealing concept reduces maintenance. Large roller bearings and centre distances increase the load capacity and service life of the components.

Expertise and support worldwide

For lower-scale applications, Nord geared motors are used, which have been optimised with regard to energy efficiency. With its profound industry knowledge, application expertise and technical support, NORD develops individual drive solutions for all types of applications in the field of bulk handling, providing worldwide support to system operators for storing, conveying, weighing, dosing, loading and unloading.