New products require new materials, and the rapid advancement and uptake in the electric vehicle (EV) and green energy industries means that demand for rare earth metals, for use in batteries and other components, is only set to increase. In order to meet global emissions targets, the industry must quickly embrace change and find ways to reduce its carbon footprint. Here John Young, APAC sales director at EU Automation, considers some of the technologies that will help mining companies work towards a sustainable future.

Legislation and guidance around sustainability is having a profound impact on all industries, not least of which is mining. For example, the International Council of Mining & Metals has introduced Mining Principles that have been designed to help realize the United Nations' 17 Sustainable Development Goals. Mining nations around the world are beginning to implement measures towards this end, as exemplified by Australia's recent pledge to invest $1.5 billion to establish Pilbara — Australia's mining powerhouse — as a hub for low-emissions industries, including manufacturing and metals and iron ore production.

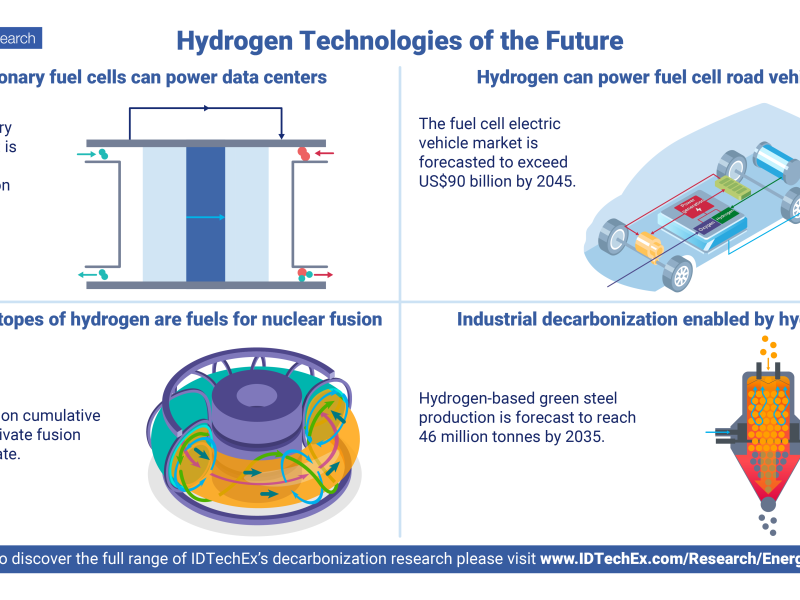

According to recent analysis from McKinsey & Company, efforts towards zero-carbon mines are likely to involve significant shifts in operations and infrastructure, such as a switch to sustainable fuels and green electricity. However, there are many current and upcoming technologies that will also be important for the decarbonization of the industry. These technologies can further boost companies' efforts or act as an interim solution before larger-scale measures can be tested and adopted.

Sustainable mining technology

AngloAmerican's vision of FutureSmart MiningTM involves the use of various technologies and digitalization methods that will each contribute to improving the sustainability of mining operations. Precision mining technologies will include coarse particle recovery, bulk sorting and ultrafine recovery to reduce energy, water consumption and waste production while increasing head grade. Furthermore, the use of sensors, artificial intelligence (AI), digital twins and data analytics will facilitate process optimization and automation to further improve efficiency, which will ultimately mean lower energy and resource input.

Autonomous vehicles have seen increased use in mining in recent years as they offer a way to increase productivity while improving worker safety and reducing cost. It is fortunate then that they also have the potential to benefit the environment, a benefit shared with many other forms of automation. Examples of technologies include autonomous trucks and long-distance trains that can make journeys more efficiently than human drivers to reduce fuel consumption, and automated drilling and tunnel-boring systems that can drill more precisely, thereby reducing drilling time and waste. Automated ventilation systems can also eliminate the need for continuous ventilation, which can further reduce energy wastage.

A benefit of automation technology is that it can often be retrofitted to existing equipment and avoids the need for an entirely new investment. Furthermore, with the field of automation advancing so rapidly, the price of automation technologies is constantly coming down. A reliable parts supplier like EU Automation can ensure that access to spare parts, whether new or obsolete, is not an issue.