In these days of personal liability for Company Managers and Directors, there’s a big difference between being a bit safer and being the safest in the world but Auckland-based New Zealand Duct+Flex reckons, hand-on-heart, it can say just that about its latest filtration products. And not only the safest, but the most energy-efficient and among some of the best value products available locally, although the company is quick to point out that it sells on quality and performance, not price.

New Zealand Duct+Flex has come a long way in the eight years since it was brought under local ownership, from an Australian company selling SpeedLock ducting. For a time it, too, supplied only metal duct and flex components to the dust and fume extraction market. Its key metal modular duct range was rebranded as LIPLOCK® and other products from the manufacturer –JKF in Denmark – were added to range. In 2010 fans, then in 2011 price competitive traditional Baghouse filters and the compact, high tech DustStorm® filters were added. DustStorm Filters have PowerPulse® compressed air cleaning and ATEX (European Safety Standard) explosion safety membranes as standard.

Dust explosions are rare but when they do occur, they can be devastating, destroying property and severely injuring staff. All JKF filters can be specified to ‘ATEX’ Safety standard. Other manufacturers can also do this but they place the explosive release membranes on the sides of the filter containing the ‘dirty’ dust laden air. This allows the explosion to escape, but it does so with a shockwave and fire burst which emerges horizontally from the unit that can be 50-60m long. It injures (or worse) anyone near the filter at the time and can cause secondary fires/damage, shutting down companies.

Wanting to provide New Zealand customers the safest products, in 2015 New Zealand Duct+Flex started to offer filters with Vertical Force Venting (VFV)®, a unique feature in that no fire leaves the filter, so it’s much safer. In the event of a fire or dust explosion in the filter, the explosive force releases vertically and harmlessly into atmosphere via vents in the roof. No fire is emitted, just the shockwave. This unique system is the most advanced and safest explosion protection system available in the world and exceeds all European /World safety regulations.

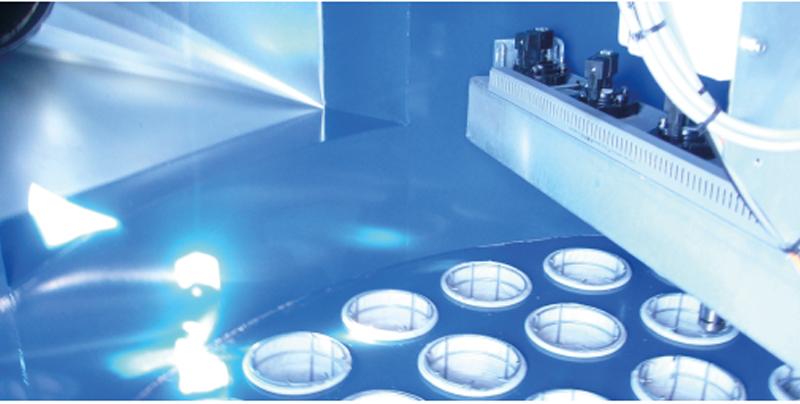

To clean the filter systems – The JKF Danish engineers came up with another world first: PowerPulse®, the most energy efficient pulsed air cleaning system in the world’s dust extraction market.

Most pulsed dust collectors can be heard going off every 30 seconds or so, wasting energy. PowerPulse® waits until its sensors inform the socks need cleaning and the mobile header unit then moves around, sensing the air flow through the filter socks as it does so. PowerPulse® also selects just enough compressed air to clean. While every other filter manufacturer uses a fixed pulse, (normally around 5 bar), PowerPulse® adjusts automatically between 1.5 and 5 bar depending upon the degree of dust buildup, NZDuct+Flex. This unique ability to think for itself saves as much as 70-90 percent of compressed air usage against any other pulsed filter system. And because the filter socks are cleaned less often and more gently, they last much longer, again saving cost.

“Of course, you would expect this technology to cost more, but due to the manufacturer JKF’s 60+ years history, and volume of production, the price is extremely competitive,” says Sales Manager, Geoff Ebdon. “Innovation in JKF means our company has now secured a well-deserved reputation of offering equipment for dust filtration that is 30 years ahead of anything else, at prices equivalent to product that doesn’t have these features.”

NZDuct+Flex’s success has bought with it increasing demand. It has also extended its range of plastic flexible ducting, stainless steel ducting, fixed and mobile Fume extraction units, and carries a wide range of material handling fans. Recent purchase of a second warehouse has allowed it to accommodate the growing inventory. Products from another leading North European supplier are about to be launched in the autumn to expand the markets and products covered.

The company strives to stock as many of the products it can right here in New Zealand.

Customers who place an order before 3pm will normally have their items shipped that day; no waiting around for two weeks while it comes from Australia or elsewhere. You can have Ducting, Fans, Fume Arms, Mobile Filters or a complete dust extraction system to handle 10,000m3/h, shipped from Auckland – today. Only unusual items or large systems that need to be ordered in from Denmark or Germany take longer. Even then, the company can give a fixed arrival date, within 24-48 hours from when you placed the order.

NZDuct+Flex employs its own installation staff who install these systems nearly every day. Of course, this gives customers surety of knowing the price is fixed and the quality of the products and performance of the whole system is guaranteed and warranted.

With just ducting installs or the simpler filter systems, where there are less safety considerations, the company installers will assist your own contactors if that’s your wish. Whoever installs, they know that they have easy and knowledgeable access to NZDuct+Flex’s huge stock holding a phone call away.

For more information on the world’s safest and most energy efficient dust filters: www.nzduct.co.nz