|

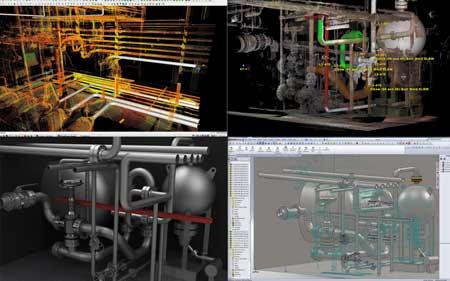

WHEN existing industrial plants need to be modified, one major issue is the poor information and data that engineers and designers have to work with – even if information does exist, often it is

The project time is compressed and overall costs reduced. Applications for the Leica system include industrial plant modifications; pipe routing; the relocation of large fabricated equipment; as-built documents; and the monitoring of structures for deformation over time. |

Email: design@novamech.co.nz

|