Some innovative manufacturing and processing sites have been shortlisted in the 2012 EECA Awards – with a diverse range of projects making the finals.

Energy efficiency is taking firm root in New Zealand’s manufacturing sector, if the 2012 EECA Awards finalists are any indication. Unveiled in April, this year’s finalists account for $60 million worth of energy savings, or renewable energy generated. And unsurprisingly, several trailblazing manufacturers, across a range of sectors, feature in the line-up. This year there are five manufacturing or processing sites among the finalists, spread throughout the regions from Whangerei to Christchurch, and demonstrating a diverse range of projects.

EECA chief executive Mike Underhill said the 2012 Awards judges were particularly impressed with the standard of entries. “Although many businesses are still dealing with the impact of the recession, there are many taking a longer term view and proactively improving energy use. This helps future-proof these organisations against price rises, and strengthens their ability to compete on the international stage. It also helps our national energy security and promotes the shift to a lower carbon economy – all of which boosts the competitiveness of New Zealand Inc.”

Heat recovery delivered savings for Life Technologies

Shortlisted in the Small to Medium Business category is Life Technologies’ protein-separation unit in Christchurch. The unit started its sustainability drive in 2008, aiming to reduce energy, water use and waste sent to landfill. After an energy audit, the company carried out a number of initiatives including installing variable speed drives on air handling units, and introducing heat recovery. Cleaning and sanitising of its ultra-filtration (UF) plant was a major water and energy user. Waste hot water is now recovered during the rinse step, stored in a 30,000 litre tank and reused in the tank cleaning process. This has cut diesel use, and brought savings of more than one million litres of water per year. Late last year, the company installed a system to collect waste heat from its two main freezer refrigeration compressors. At current performance, this is on track to save more than 100MWhrs of diesel per year by preheating incoming water supply to the hot water boilers. Across all its initiatives, diesel use at the Christchurch site has more than halved.

Nelson Pine tackles heat plant and motor efficiency

Shortlisted in both the Large Business and Energy Management categories is Nelson Pine Industries, the largest electricity user in the top of the South Island. As such a large consumer, any efficiencies the company achieves benefit the region through easing pressure on supply. With a close eye on the sensitivity of its MDF manufacturing process, the company commissioned a site-wide energy audit then introduced the recommendations in careful stages. First it tackled heat plant efficiency by improving furnace control, reducing dryer airflows, and automating its pre-steaming control. Combined, these measures reduced its wood fuel bill by $800,000 a year. Optimisation of its motor systems started in early 2012 and was carried out in four phases. By July that year it had installed variable speed drives to control air flows on 18 fan lines, and continued to fine tune and optimise the systems to gain further efficiencies. Electricity savings are now worth $500,000 a year and are expected to improve even further. The project has also had a spin-off benefit of reduced maintenance costs.

Dominion Salt boosts production and improves efficiency

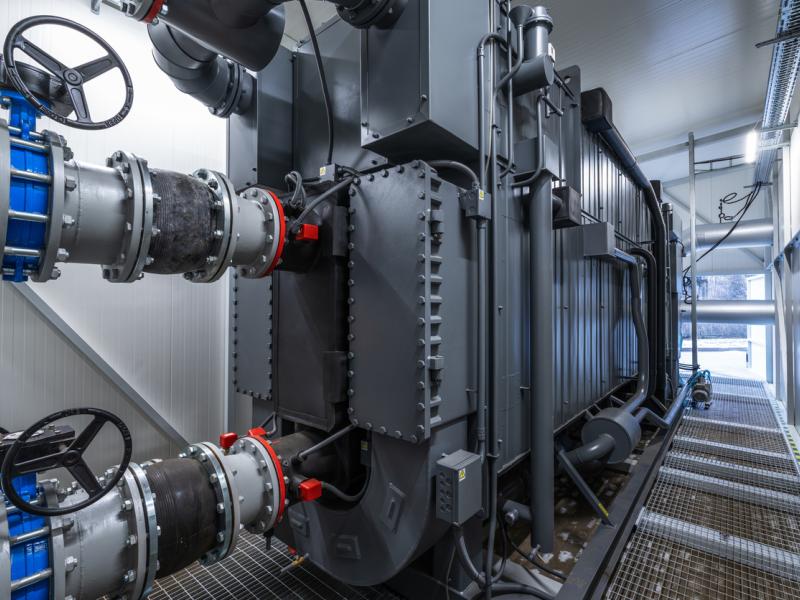

Dominion Salt and Aurecon New Zealand are joint finalists in the Innovation category thanks to a vacuum plant upgrade that has boosted plant capacity by 63 percent and allowed the simultaneous production of food and pharmaceutical grade salt, compared to previously where the plant had to switch between production runs. The project has improved overall energy efficiency by 48 percent – natural gas used per tonne of product is down 33 percent from 4.25 GJ to 2.84 GJ, and steam use and carbon emissions have also reduced by around a third. At current production levels the upgraded plant is saving the company more than $500,000 per year in energy costs which is expected to increase further when it reaches full plant capacity of 76,000 tonnes of salt production per year. As well as allowing Dominion Salt to keep up with expanding export demand, the upgrade has given the company a competitive advantage by lowering input costs.

SCA Hygiene cuts CO₂ emissions with geothermal

Award finalists aren’t showcasing just energy efficiency – there are also groundbreaking renewable energy projects on display. SCA Hygiene, the manufacturer behind common household brands such as Purex and Tena, is a finalist for the Large Business award. It replaced natural gas boilers used to produce the steam required by paper machines at its Kawerau site with direct clean geothermal steam. SCA’s new geothermal-powered plant generates 16barg of clean steam, 24 hours a day, 363 days per year. This change alone cut the plant’s CO₂ emissions by 39 percent, and has enabled further energy savings. For example, after use, the clean geothermal steam is turned into condensate (clean, warm water) which is also used in the paper mill. This cuts down on water use, and also the energy used to heat it. Using geothermal steam as an energy source has a number of benefits for SCA Hygiene: it’s reliable (being available 24/7) and is accessible, being right under the plant. It’s also highly efficient as there is no energy conversion, and the price is stable. SCA buys its clean steam from Ngati Tuwharetoa Geothermal Assets, a wholly-owned commercial subsidiary of Ngati Tuwharetoa Settlement Trust. This means most of the revenue generated stays in the Kawerau area.

Biofuel replaces coal at Golden Bay Cement

Golden Bay Cement is another example of a large operation tapping into an innovative renewable energy source to cut its CO₂ emissions. The company has been increasingly substituting coal burned at its Whangarei facility with wood fuel, mainly sourced from local construction and demolition waste. It’s now substituting, on average, 30 percent of coal with biofuel. This has delivered annual energy savings worth $3 million, and reduced CO₂ emissions by 58,000 tonnes per year. Golden Bay Cement’s entire biofuel-substitution system was designed specifically to suit the company, and in-house ingenuity reduced installation costs significantly. International experts costed the system’s design and supply options at around $5 million – but after an in-house review, the company found a way to achieve it for a fraction of the cost, including using re-used material. As well as lower energy costs, Golden Bay is paying less for its raw materials, as it needs less high-grade limestone for production, thanks to the lower ash content in the wood fuel compared to coal.

Email: Miranda.James@eeca.govt.nz

EECA Award finalists showcase excellence in efficiency

Energy Efficiency

Tuesday, 01 May 2012