By Matt Hale, International Sales & Marketing Director, HRS Heat Exchangers

The first duty of any food or drink manufacturer is to supply its consumers with a product that is safe. Due to their organic nature, some of the most wholesome and natural products, such as milk, cheese, yoghurt, fruit and vegetables, and meat products are all subject to spoilage by biological organisms including bacteria and fungi. While maintaining good equipment hygiene through the use of effective protocols, such as Cleaning-in-Place systems, is essential, it is also economically important that perfectly usable product is not discarded as part of routine cleaning operations.

In 2014, for the three most common causes of food poisoning (Campylobacteriosis, Salmonellosis and Listeriosis) there were almost 4,500 cases associated with food-borne transmission in New Zealand1. While this is a huge improvement on historical levels, there are indications that issues involving the contamination of fresh produce are increasing2.

New food standards for both Australia and New Zealand are developed by Food Standards Australia New Zealand (FSANZ), a statutory authority within in the Australian Government’s Health portfolio. Food safety codes are enforced by a number of organisations: state and territory departments, agencies and local councils in Australia; the Ministry for Primary Industries in New Zealand; and the Australian Department of Agriculture and Water Resources for food imported into Australia.

In terms of the systems used by the food and drink industry itself, as elsewhere in the world, Hazard Analysis and Critical Control Point (HACCP) principles are widely used in most sectors. As a result, many areas of controlling food safety, such as ensuring equipment is sanitary and preventing contamination, use common approaches across a wide range of food and drink sectors. One of these is the use of automated and semi-automated Clean-in-Place (CIP) systems for processing equipment, such as pipework, heat exchangers, pasteurisers, fillers, pumps, etc.

CIP systems offer a number of advantages over manually disassembling, cleaning, checking and then re-assembling plant. Not only are they much quicker and less labour intensive, but they also reduce costs and allow more frequent and therefore effective routine cleaning of systems to be carried out. This is a big benefit in terms of maintaining food safety and preventing the growth of microorganisms which could spoil products or pose a risk to health. There are many different types of mechanical and automatic cleaners employed in the food industry, using everything from plain water or suitable cleaning chemicals, through to ultrasonic and UV cleaning techniques. However, before any CIP can be carried out, as much product as possible must be removed from the equipment to be cleaned.

Traditional flushing and ‘pigging’ systems (which physically push product through the system) have been used for this purpose, but they often result in the loss of product, the value of which can soon add up. It has been suggested that globally up to one quarter of food produced is lost within the food supply chain, with the largest per capita losses occurring in North America and Oceania3. Although losses during processing are relatively small (around five percent of the total losses from the food supply chain), this waste could be worth as much as AUD2.36 billion a year to the Australian economy4, not to mention the environmental and climate costs associated with the land, energy, water and fertiliser used to produce the raw ingredients, and energy and waste costs from food processing.

The challenge for food and drink businesses is therefore to implement effective and rigorous CIP regimes which meet all necessary hygienic standards, but to do so in a way which minimises the loss or degradation of saleable or useful product. This is where two recently developed systems from HRS Heat Exchangers come in.

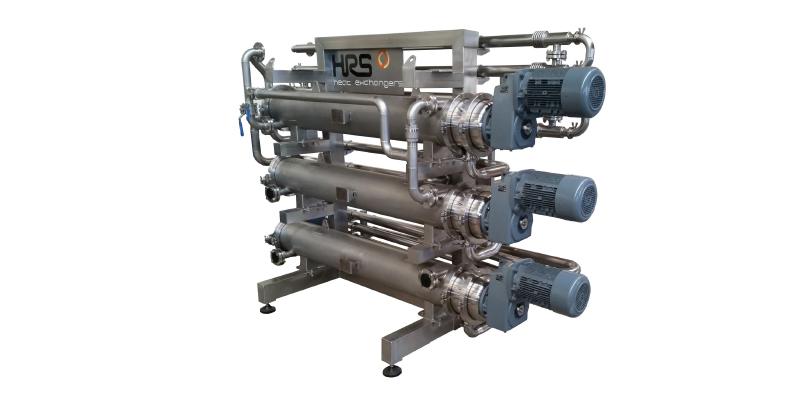

The first development uses the design of the HRS R Series of scraped surface heat exchangers to physically remove product without the need for additional pigging systems. The R Series is suitable for a range of heat transfer applications and its unique design enables high viscosity products to be pumped with reduced back pressure and lower energy use. The helical spiral which scrapes the surface of the tubes to prevent fouling in normal use, can also be run in reverse; thereby enabling valuable product to be recovered prior to routine cleaning or product changeover. This design feature means that the HRS R Series can be emptied of the majority of product, without the need for additional pumps or pressure systems, reducing both capital and running costs.

The second development is the HRS Product Recovery System. This combines continual monitoring of a set parameter (for example Brix, pH or viscosity) and combines it with the three-way valve technology which is already employed in every HRS pasteuriser or steriliser. Working together, these two systems ensure that all product which meets the set parameters is utilised and only that which falls outside (for example, that diluted prior to or during CIP) is discarded. Furthermore, such monitoring helps to validate the effectiveness of CIP and ensures that following a cleaning cycle, only product that meets specification is allowed to proceed.

As well as the financial benefits associated with recovering more product, further advantages include a reduction in the amount of waste generated which in turn decreases disposal costs such as storage, transport and treatment. These various savings add up and mean that this type of equipment rapidly pays for itself. Crucially however, the effectiveness of CIP and the requirements of HACCP analysis continue to be met, ensuring food safety remains paramount.

Details, HRS Heat Exchangers ANZ

Ph: 09 889 6045; E-mail, info@hrs-he.com

1 Annual Report Foodborne Disease in New Zealand 2014: https://www.mpi.govt.nz/dmsdocument/10370-annual-report-foodborne-disease-in-new-zealand-2014

2 https://www.odt.co.nz/lifestyle/food-wine/news-features/produce-contamination-increasing-problem

3 Kummu, M. et al. 2012. Lost food, wasted resources: Global food supply chain losses and their impacts on freshwater, cropland, and fertiliser use. Science of the Total Environment 438: 477-489. https://core.ac.uk/download/pdf/82625409.pdf

4 Calculation based on total Australia food retail turnover of AUD141.4 billion in 2012-13 representing 75% of primary food production. See http://www.agriculture.gov.au/SiteCollectionDocuments/ag-food/publications/food-stats/australian-food-statistics-2012-13.pdf