So you think you’ve got an idea of how to improve your production processes but you’re unsure whether the equipment will fit or that the footprint is right?

Rather than going through a time-consuming fully-fledged design project, EQM can now put together some 2D layout designs and if the idea stacks up, can then take it one step further into a 3D design.

EQM’s Anthony Bloxham says it’s a wise move to put together some 2D drawings to help get a better understanding of what you’re considering before making a significant capital investment in plant development.

“We’ve got vast experience in putting together efficient high performance conveyor systems and if we start with an idea or a problem that needs a solution, we can design a solution that then can be either agreed then or expanded on with a 3D concept.

“Because we have experience in using a wide range of equipment we can match everything together to ensure that it performs to expectation and takes into consideration placement of staff and ongoing maintenance.

“It’s a more calculated and strategic way of looking at future proofing your production line.

“We recently provided the service to a nursery that grew potted plants and they wanted a system to help stack and sort prior to order picking and distributing to customers.

“We designed a conveyor and racking system in the existing space available and worked out the right placement and positioning of staff. By doing this in a 3D model we were able to provide a better indication of what the project costs would be and the future operating cost savings.

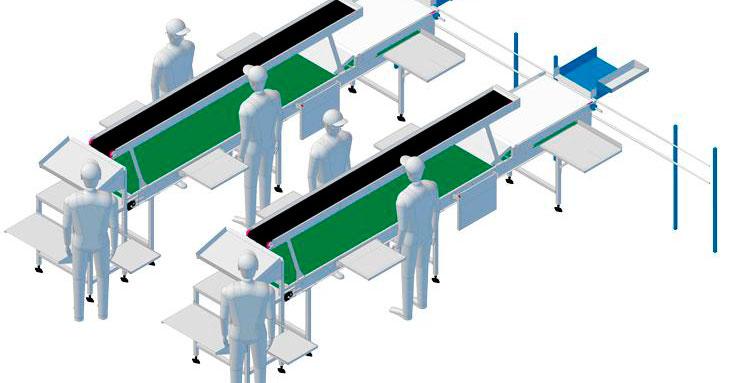

“Another example is the conveyor and packing table solution EQM designed and developed for a fruit packhouse to bag apples more efficiently and faster.

“Not only did we design an effective solution but we were also able to work out the right placement of staff.”

FREEPHONE 0800 147 847

EMAIL SALES@EQM.CO.NZ

WEB WWW.EQM.CO.NZ