Power transmission and conveyor chain are the two common chain drives found in industry, and although their purpose is different, what is common with chain drives is that they wear. The phrase “stretch” is frequently used when referring to the level of elongation of a chain.

The reality of chain elongation is each chain link consists of a collection of surfaces which slide against each other as the chain articulates, such as wrapping around a sprocket. Plain bearing surfaces provide high load carrying capacity for small shaft dimensions in comparison to rolling bearings, but also have lower speeds due to higher friction with sliding surfaces rather than rolling.

On a typical roller chain, a pair of bearing surfaces can be found at every pin on both the inner and outer plates, and the wear of these surfaces determine elongation. The allowable elongation of chain depends on the application, however less than 2% increase in length for transmission chain is common. Although this may seem insignificant, this elongation will cause the chain to start riding up on the sprocket teeth and in more extreme cases can ‘jump off’. Once a chain begins to elongate, the level of wear will begin to accelerate on both the chain and sprockets till catastrophic failure or replacement.

Minimising chain elongation can be achieved by the following:

- Improved lubrication.

- Reducing chain tension.

- Larger sprocket sizes to reduce the angle of flex.

- Replacing sprockets when the chain is replaced.

- Increasing the contact area between pins and bushings (multiple strands, larger chain size).

- Increased hardness of the pins and the bushings.

Limiting the level of wear is one of the key maintenance tasks for chain in order to achieve better service life, and the proper lubrication of the chain plays a key role in maintaining a suitably designed chain drive.

Chain lubricant

Selecting oil with suitable viscosity for the application is important to ensure that it reaches the required surfaces within the chain. If the oil is too thick, it may not be able to reach the chains internal surfaces while an oil with too low a viscosity or lacking in performance may not provide sufficient wear protection.

SKF offers two ranges of oil to cover the requirements of most industrial chain applications for medium temperatures and high load/temperature, and a range of food grade chain oil range specifically developed for food and beverage applications where high temperature, high humidity and low temperatures are critical factors to consider in the selection of the correct oil. The whole range of food grade chain oil is NSF, H1 approved, therefore fit for the food and beverage industries.

Automatic lubrication

In situations where the chain needs frequent lubrication, or where the chain cannot be accessed safely or easily, a SKF SYSTEM 24 lubricators may be suitable to ensure the correct quantity of lubricant is delivered over a set time period and reduce oil consumption.

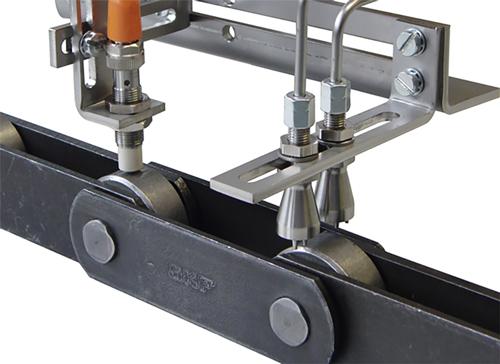

Conveying chains require continual lubrication to reduce high levels of friction that can result in chain wear, high energy consumption and unplanned production stops. In most plants, lubrication is applied manually – a task that requires the chains to continue running while production is stopped. In these cases, an SKF Oil Projection System can direct specific amounts of oil to only the pin locations to reduce unnecessary oil consumption, increase chain life and eliminate manual lubrication requirements.

SKF has documented success with oven conveyor chain lubrication where significant improvements in the operation were gained while reducing the risks of contamination and safety hazards.

For information email: customerservice.nz@skf.com or visit our website www.skf.com