Control multiple compressed air stations centrally – electronics expert Weidmüller only needs one single control for its five compressed air networks from now on. All information can be clearly displayed on BOGE’s airtelligence provis 3. All components can be controlled individually, and pressure ranges can be altered as required. In this way Weidmüller has been able to optimise its monitoring and measurably improve efficiency.

Compressed air is required in the company for assembly processes, as process and control air as well as for electroplating. To this end, Weidmüller installed five separate compressed air networks, each featuring up to seven compressors and other components. The company primarily uses BOGE compressors, but also uses air compressors by other manufacturers. The machines cover many performance levels within a pressure range of 7 to 8 bar. In recent years, the larger networks have been controlled using an individual control, while the smaller ones have been controlled via a cascade control using pressure sensors. Weidmüller came to BOGE because they wanted a new control that would incorporate all five compressed air networks and offer a better overview. Other requirements included a reduction in idling and thus increased efficiency. They also wanted to keep operating pressure and power consumption to a minimum.

Successful field test

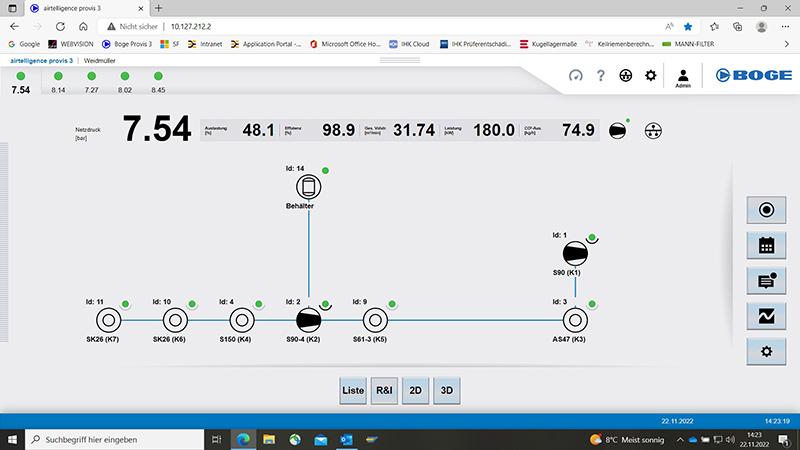

In addition to the existing BOGE S 150, S 20, S 15 and S 29-2 compressors, there are two S 90-4s, one S 60-3 and one S 40-3 in use, which feature the focus control 2.0. “We can read out the temperature, system pressure, network pressure and operating statuses directly at these machines”, explains Jens Mühlbauer, project manager at Weidmüller. “This in itself is a huge advantage over older systems, which usually only display information about faults, load and idling as well as on/off.” But with the airtelligence provis 3, Weidmüller is now going one step further. The functionality and operation of the interlocking control were first trialled in a field test. This went so well that Weidmüller promptly decided to go ahead with the installation. The new control is backward compatible and easily integrates all models via Modbus Interface Module 2.0. Furthermore, the airtelligence provis 3 together with the Open Platform Communications Unified Architecture (OPC UA) standard enable secure and reliable communication with higher-level systems, for example a control room or energy management systems, based on the companion specification OPC 40250-1 Compressed Air Systems – Main Control System. Weidmüller therefore now uses one central control for all components in the five compressed air networks.

Optimal adjustment to direct demand

The control is installed on a powerful industrial PC and integrated in a switch cabinet. The individual networks are each connected to the new control via a single patch cable. Within the network, the signals of the control are distributed to the individual compressors via the Ethernet switches. “Thus the conversion was complete in next to no time”, says Jens Mühlbauer. “We provided our own power supply units and Ethernet switches to further boost the signals from the control. The transfer rate is very high and the system is very stable.” Less compressed air is required at Weidmüller at weekends and on public holidays. The control regulates this intelligently. It automatically selects the optimal compressor combination and optimises the load and idle times. It can also manage fluctuating compressed air generation in different shifts. Over-compression can be avoided. Energy management by the airtelligence provis 3 includes setting machine priorities. For example, a 90 kW compressor is connected to take precedence. It supplies Weidmüller’s entire electroplating shop with both compressed air and heat and must, therefore, run constantly. The whole control was programmed to optimise efficiency. To this end, the volumetric flow rate generated is analysed regularly.

24/7 overview

The user can consolidate maintenance intervals, optimise running and is automatically notified when the integrated machines require maintenance. This has a positive effect on the operating life of the machines. The airtelligence provis 3 offers a perfect overview of all networks. For example, the operating hours are directly visible. “You can always keep your eye on utilisation, the current power consumption and the free air delivery of the individual systems”, says Jens Mühlbauer. “In the past, I had to go to every machine to get the information locally. It wasn't very handy at all.” Another advantage: improved energy efficiency. The electronics expert has been able to increase this by four to five percent. “That’s quite a lot in a system of 450 kW”, says the project manager emphatically. “This allows a significant improvement compared to systems that run purely via a cascade control or pressure switch – not least because the pressure can be reduced on holidays and at night using redefined pressure ranges.” This can be done minute-by-minute and for every compressed air network separately, using a few touch commands, without having to laboriously search through the program. According to Mühlbauer, operation is child’s play. The information of the individual networks and compressors can be displayed on several end devices. Weidmüller is also set for the future because the airtelligence provis 3 can be expanded indefinitely as desired. Any further components that are added to the individual compressed air stations or additional networks that are formed can be easily integrated.