In automating factory functions, larger companies have typically turned to expensive, complex industrial robots and expert in-house engineers. So, what’s the appeal of smaller collaborative robots (cobots) and why are an increasing number of larger businesses looking to this technology to complement their existing production set-up and accelerate their factory automation?

“Large companies around the world are embracing cobots for various reasons, and the benefits are clear,” says Masayuki (Masa) Mase, Country Manager Oceania for Universal Robots.

And while he believes that Australia and New Zealand still have some way to go in terms of robot adoption, the latest statistics reveal a steady upward trajectory. “According to the IFR World Robotics, Australia has around 73 robots per 10,000 employees while New Zealand sits at 55 robots per 10,000 employees. While this statistic is still well below world leaders such as South Korea – with a staggering 932 robots per 10,000 employees – on the ground, we are seeing more enquiries and curiousity when it comes to deploying robots at an organisational level.”

Looking to demand in Australia, handling operations (68%) and the food industry (28%) account for the largest number of robot installations. In New Zealand, handling operations (55%) and assembling (22%) make up the majority.

With this in mind, Masa believes that large local employers should stay ahead of the curve by embracing automation. He shares five key reasons why large manufacturers are opting for cobots as follows:

1. Cobots are being used to complement traditional industrial robots

It’s not a question of either/or for large companies, as Masa explains: “Traditional industrial robots are an essential part of operations for many factories. However, what we’ve learned from large factories is that they’re seeking increased automation and greater flexibility.”

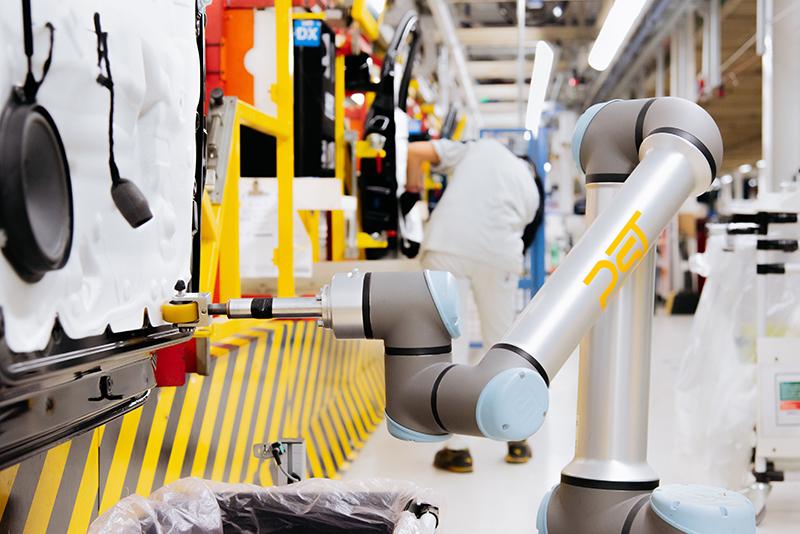

Part of the attraction of cobots is that they can be swiftly integrated into existing production lines without the need for significant modifications to the workflow. And, because they are compact with a small footprint it’s often possible to introduce cobots without making changes to the factory floor – definitely a big plus when space is at a premium. Universal Robots cobots also come with an industrial standard inferface like ProfiNet, ProfiSafe and other Ethernet based protocols, which are mandatory in larger production lines and accelerate integrations.

But the most exciting part is when cobots are used to work with traditional industrial cobots. Take Stellantis, a leading global automaker and provider of innovative mobility solutions, which uses cobots across several parts of its production. In Italy, the company already had a sophisticated powertrain plant with traditional industrial robots. Within this highly automated environment, the factory now uses cobots at a station for oil pan dispensing to maximise production. The solution has increased quality and safety and reduced downtime caused by this station to zero.

2. Labour and skills shortages are forcing a rethink of job design

Large companies are not immune to the labour and skills shortages affecting manufacturing businesses across most markets. Companies have to work harder in today’s current environment to attract and retain workers. In fact, recent research suggests that large companies have the longest way to go when it comes to employee retention.

Cobots can help companies increase production capacity and output without needing to hire more employees – an attractive benefit in a competitive labor market. But they can also have a more profound impact on workplaces by relieving workers from repetitive and physically challenging tasks, creating safer working environments, and freeing up time for employees to take on more meaningful tasks with potential for upskilling and improved morale. It’s pretty common to see employees naming their cobots and it is often the operator that comes up with new uses for collaborative automation in the factory. “Our larger customers are experiencing all these benefits and, in a tough recruiting environment, it gives them a fighting chance of attracting and retaining the people they need,” comments Masa.

3. A trend towards simplification, modularity and increased flexibility of the production line

Cobots offer a couple of important features that traditional industrial robots lack. They are specifically designed to have an easy user interface, which means specialist expertise is not generally required for reprograming. They’re also portable and, while many companies are happy to purchase a cobot with a single task in mind, an increasing number of businesses, including larger companies, value the flexibility that cobots offer.

Cobots are portable and relocatable. Their position and roles in production can be modified and repurposed as gaps appear on the manufacturing floor. They can be hung from ceilings, mounted to a rolling cart or even placed on a mobile robot. Multiple programs can be stored and reloaded to tackle product variations, and adjustments can be handled in-house. There’s nothing new here – it’s what cobots were designed for, but the desire from larger companies to harness that flexibility and turn towards more modular approaches to production is growing as they respond to increased demand for personalization and more uncertain market conditions. “Global organisations are rethinking their automation, productivity, and supply chain, and with that comes new approaches to factory layout,” he adds.

4. Technical advances have created new possibilities for cobot technology

In the years since cobots were first created, the pace of technological change has been rapid. In the last few years in particular, machine learning and artificial intelligence have started to transform industrial automation – and cobot automation is leading the way. “Large companies are well placed to start to harness these new capabilities, for example using cobots with machine learning to identify trends and reduce process inefficiency. This combination of cobots and AI/machine learning will continue to unlock challenging applications once thought impossible.”

5. They see the same benefits as smaller companies

Finally, large businesses are turning to cobots for the same reason as businesses of any other size: because cobots can help even the biggest businesses to improve productivity and output and enhance quality. Cobots can enable companies to reduce downtime and sometimes even to run 24/7 production. Whether or not production time is extended, robotic precision means cobots can improve the consistency of throughput and create more stable output quality. These factors mean that the return on investment tends to be fast.

For example, by leveraging a UR5 cobot equipped with a custom gripper, Melecs EWS in Austria was able to significantly improve the packaging process for printed circuit boards, increasing productivity by 25%. The cobot, handling several steps simultaneously and working flawlessly in three-shift operations, has allowed the company to package two million circuit boards annually, underscoring the effective role cobots can play in enhancing manufacturing productivity.

He concludes saying that Universal Robots is actively working with manufacturers in deploying cobot technology that both simplifies and digitizes automation in their production environments. “In collaboration with our strong ecosystem partners, we are managing fleets of cobots on factory floors to improve productivity and alleviate labor shortage issues. It is very clear that cobot technology continues to hold great promise for large manufacturing companies.”