Martin Broglia, Managing Director for Bonfiglioli Australia believes that choosing the right heavy-duty gear unit all comes down to three key requirements: “Price, quality and service”.

And while these requirements are obvious, making 100% sure that both the supplier and the product meet the brief, isn’t always clear cut. This is because heavy-duty applications require only the best.

“Skimping on price or quality can cause unnecessary downtime on a plant, quarry or mine”, he adds.

Heavy-duty Check List

Martin shares some of the key factors to consider when choosing a heavy-duty gear box. “When choosing a supplier, make sure that they tick the following boxes”,

- A good service experience

- In-depth knowledge and understanding of the brief

- High torque output

- Mounting flexibility

- Certification

- Long service life

- Suitable for harsh environments

- Low maintenance costs

- Versatile

- After-sales service and maintenance

- Customisable – can add accessories and there are a range of options to choose from

Meet the HD Series

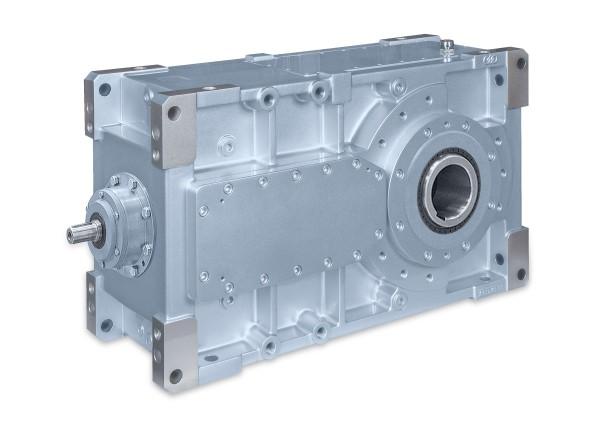

“For Bonfiglioli”, he says “The HD series of heavy-duty gearboxes and geared motors meets the brief,”

Thanks to high quality materials and an optimized design, this series can operate in the harshest environments, as well as in explosive atmospheres, with low maintenance costs and long-time service intervals.

“The output shaft can be chosen both in the parallel (HDP) or right angle (HDO) configuration and to always ensure the minimization of mounting space. The HDx series can be deeply customized thanks to an extremely wide options and accessories portfolio, thus matching most of the requirements of a large applications number,” explains Martin.

“The HDO series is particularly suited for bucket elevators. It acts as a one-stop complete drive solution, and offers highly transmissible power, extensive customisation, an external cooling-system and quiet operation.”

Speaking to the success of the range locally, Martin says that the HD series remains of the company’s top-sellers. “We continue to enjoy success in the heavy-duty industry and customers know that they can turn to us for reliability in terms of product and service”, he concludes.