Many of New Zealand’s leading food companies are using EQM Industrial as their “go to” equipment firm for conveyors, rotary tables, gear drives, labelling machines and componentry.

During 2015 EQM supplied general and tailored solutions that have improved the productivity for a range of food companies from dairy through to fruit and confectionary.

A new food facility called on EQM to supply gear drives and conveyor components that was needed for a unique packing system. We recommended STM UMI & RMI Series as they are a smart gearbox that easily drives rotary tables and prevent the tall tubes from being knocked over.

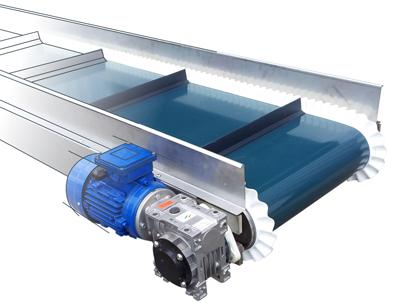

Another project which started out as designing a conveyor line solution, led to a new conveyor system with several conveyors of various types as well as a rotary table.

The food producer wanted a hygienic conveyor system for dry goods and needed to ensure there would be no build-up of dry matter along the production line.

An apple pack house has a new bagging tray filling system created by EQM Industrial.

Increased demand for bagged apples had caused some problems in the packing process so we reconfigured it and added packing lanes tailor designed for bagging fruit but also to tray pack Z packs and RDT.

Nothing is sweeter than coming up with the right solution to a sticky problem and that’s just what EQM did with a conveyor system for a honey business.

The honey business was looking for a new solution to de-box (a decontamination process) its hives.

A new skate conveyor system was installed, which can easily be converted into an automatically motorised system.

EQM installed a long-lasting stainless steel gear drive at a dairy plant to stir a starter fermentation pot used in the process of making cheese.

The plant produces tonnes of cheese every day and the gear drives used to stir the starter pot can work up to 24 hours a day, seven days a week.

Cheese is the most complex of the dairy products, involving chemical, biochemical and microbiological processes. In cheese making, the “starter” is a culture of carefully selected lactic acid-producing bacteria.

Aluminum gear drives would only last about eight months of heavy use and a better performing alternative was needed.

Contact 0800 147 847, sales@eqm.co.nz, www.eqm.co.nz