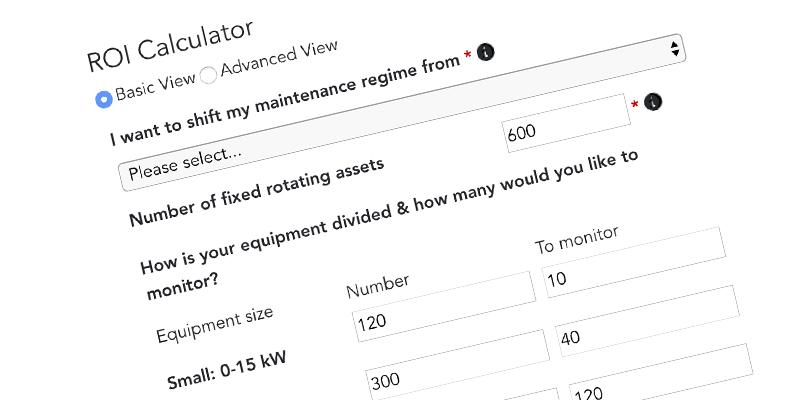

A calculator the developer says will save manufacturing and industrial business hundreds of thousands of dollars a year, will help asset owners, reliability and maintenance teams, operations and technology executives quickly estimate the financial benefits of condition-based maintenance (vs. reactive and preventive maintenance) in their organisation.

Built by engineers for engineers, MOVUS’ ROI Calculator provides either a basic or advanced interface to help professionals understand the potential cost savings they could make by minimising unplanned downtime and reducing maintenance costs, while extending equipment lifetime, and saving on energy usage.

The ROI calculator is a ‘quick and easy-to-use’ resource for maintenance staff, planners, plant and production managers, operations professionals and executives to develop a business case for condition-based maintenance in their organisations.

“As the voice of the Industry 4.0 technology in Australia, we are committed to educating the relevant industries on the benefits – financial, operational and environmental – of condition-based equipment maintenance,” said Brad Parsons, Co-Founder and CEO of MOVUS. “We are simultaneously dedicated to then delivering the actual solutions needed to achieve these outcomes. We have done this by developing the most cost-effective, and easy-to-use and technologically-advanced solution in our FitMachine platform. Businesses can literally save hundreds of thousands of dollars by moving to condition monitoring, so it’s a no brainer to instigate an initiative like this.”

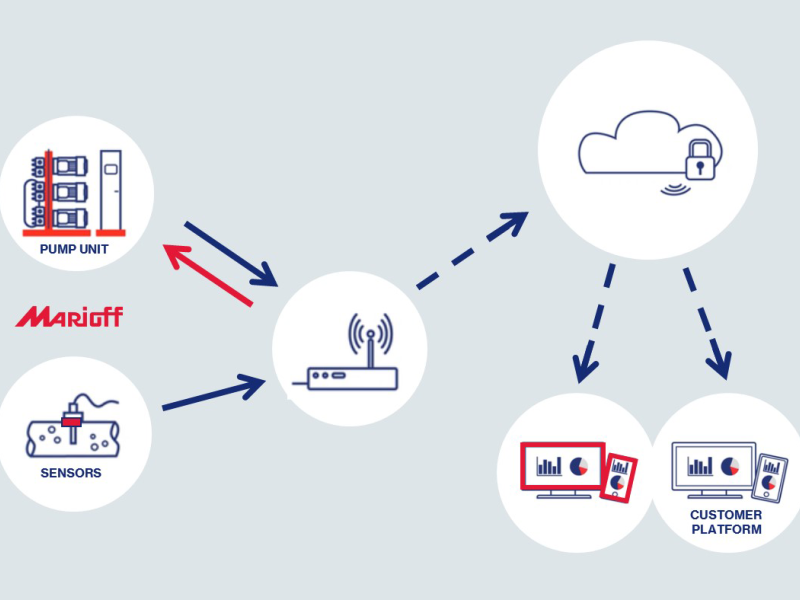

FitMachine is a condition-based maintenance solution that detects machine failures in advance using artificial intelligence and machine learning. The solution comprises an industrial wireless Bluetooth sensor, industrial gateway, mobile application, analytics and trending dashboards, and artificial intelligence engine. The system automatically monitors equipment 24x7 and learns what the normal operation of machinery is to detect any abnormalities and alert the organisation before failures occur. The insights provided are machine health, degradation, utilisation, energy consumption and more. Get get started with the ROI Calculator here

www.movus.com.au/roi/