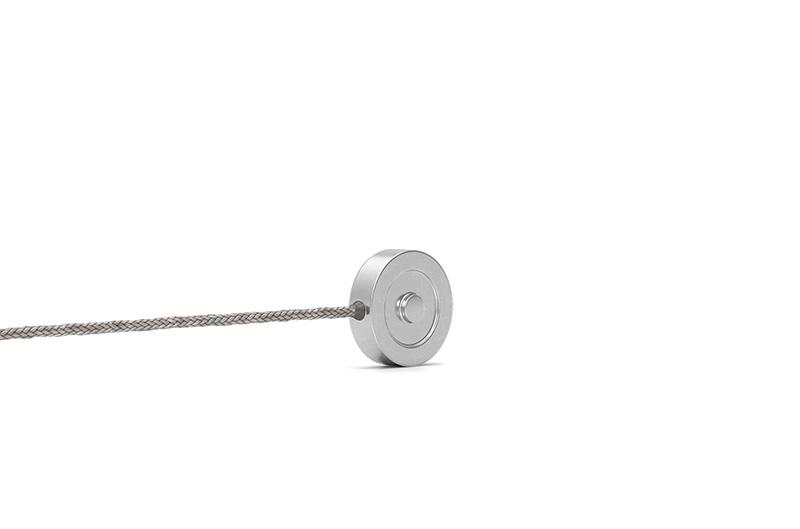

This miniature load button sensor LLB250 has only a 12.7mm × 3.9mm footprint, but it packs a powerful punch.

LLB250 is a Miniature Load Button in a class of its own. Capable of measuring compression forces up to 113.4 kg with a footprint of just 12.7mm diameter and 3.9 mm in height, it is an extraordinarily powerful and precise miniature sensor. It features a custom single-gauge design for robust integration with the sensor case and very high accuracy and reliability. The single-gauge design, eliminates inter-gauge wiring, leading to enhanced calibration performance. A customised strain element allows increased strain measurement around the active sensor element that reduces reproducibility errors and installation mishaps.

The diverse and durable LLB250 sensor is designed for press or inline compression applications, such as measuring loads on a turbine shaft or gauging forces on a CNC workpiece. The sensor has a highly flexible 34 AWG, 4-conductor, 1.5 m long braided shielded cable. FUTEK also offers custom sensor versions that can be optimised to meet your requirements.

Range and flexibility

LLB250 series offers load buttons in two capacity options that measure compressive loads from 45.35 up to 113.4 kg. Its highly flexible mounting options include securement from the outer lip, retention with screws, or mounting inside a counterbore hold.

Made to be accurate

The LLB250 delivers a remarkably high natural frequency (starting at 33.0 kHz and going up to 41.7 kHz) which provides a fast response time that benefits accuracy and cycle time reduction. The precision of the sensor is also augmented by its high stiffness, which leads to a very low deflection of 0.013 mm. In addition, special design and manufacturing touches further enhance the sensor’s performance, such as a highly customised strain element that greatly reduces solder joints, increasing the sensor’s reliability.

Robust construction

The stainless-steel body provides outstanding strength and corrosion resistance and provides enhanced protection against physical damage in addition to withstanding other harsh environmental conditions. A special heat treatment process has been applied to the flexure to improve durability, extending the life cycle of the sensor. Additionally, the metallic load cell housing significantly reduces interference and unwanted environmental conditions that would affect the accuracy and reliability.

Every single sensor made is rigorously tested by FUTEK’s world class calibration department

About FUTEK: FUTEK Advanced Sensor Technology, Inc. is a U.S. Manufacturer of load cells, torque sensors, pressure sensors, multi-axis sensors and related instruments and software. FUTEK supplies test and measurement products to many industries, especially medical, robotic, and aerospace

FUTEK Advanced Sensor Technology, Inc. is represented in Australia and New Zealand by Metromatics. www.metromatics.com.au