Now that New Zealand has building energy performance standards such as NabersNZ, measuring and verifying your energy use is a key component to meeting your desired performance rating.

Before you get to the measurement and verification (M&V) part though, energy conservation measures need to be put in place to help achieve your NabersNZ or other energy performance goals (such as reducing costs). As many organisations are faced with doing more on a smaller budget, the idea of buying new equipment may seem out of the question.

If you’re faced with this dilemma, energy performance contracting (EPC) could be your solution. By implementing an EPC, you will be able to leverage the flexibility and resources of the private sector to pay for energy saving capital upgrades using the future energy savings.

The initial capital investment required to do the work is provided by the private financial community and the actual services, such as energy equipment retrofits, are delivered by energy services companies (ESCOs).

The financier is paid out of the accrued energy savings, with the ESCO guaranteeing a certain level of savings or performance. By partnering with industry professionals (businesses who employ EMANZ EnergyMasters for example), you gain the expertise, perspective and resources to implement intelligent management systems that improve the efficiency of your buildings and simplify the work for your maintenance professionals.

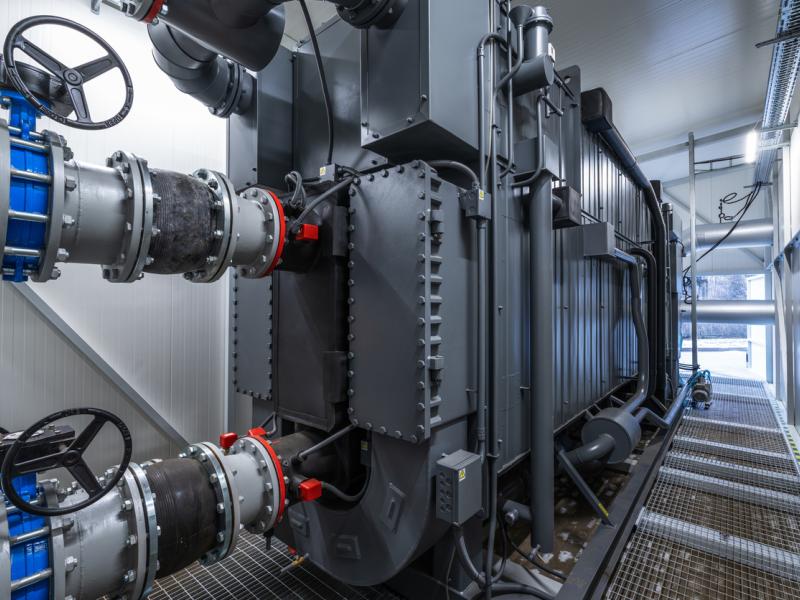

As an aside, inadequate maintenance of HVAC systems is often a source of significant energy waste. Finding the right expertise to rectify that is not always easy.

With an EPC, facility managers can bundle a variety of capital upgrades into one project, creating a significant guaranteed annuity that is financed over a 10 to 20-year period.

Energy retrofits (energy efficient lighting upgrades for example) can easily achieve up to 30 percent energy savings, and generate operational and environmental savings, while reducing carbon emissions and pollution.

But as already noted, measurement of energy performance is key to capturing your results and generating savings. This is where an M&V strategy is important for assuring that projected savings occur, to identify opportunities that might impact greater efficiency, and as a means for quantifying and reporting emission reductions.

[sub head] M&V methodology

Energy savings can be collectively measured using whole facility (utility meter) methods or, if you are a tenant in a multi-tenanted building, through the use of individual retrofit equipment and methods that isolate your energy usage (and not energy used by other tenants or energy that the landlord should be responsible for).

As part of an EPC, organisations can evaluate the nature of the programme and develop a solution that properly balances the reduction in savings uncertainty and the cost to achieve that reduction.

Individual retrofit approaches have the potential to remove most uncertainty, but without the proper measurement equipment in place, these approaches often only demonstrate the savings available from the fully functioning conservation measure.

Whole-facility approaches are best at capturing the interactive effects of an energy management programme and are more cost effective for long-term measurements.

However, if whole-facility analysis is used on its own, only changes in whole facility performance are noticed, while the actual source of waste is often left unidentified. Additional analysis is required to pinpoint the cause in order to remedy the savings loss.

A well-rounded measurement and verification plan also includes performance monitoring. Measurements shouldn’t be limited to determining the magnitude of the achieved savings, but also should be used to identify degradation in performance.

A system that identifies the time frame and quantity of energy used can be your most valuable resource. These monitoring systems help ensure consistent savings and allow for more efficient use of maintenance and operation personnel’s time.

Measurement, to determine the savings, and monitoring, to identify the performance of the leading indicators of savings, are essential to the success of your EPC program.

Failing to meet the energy savings goals of any program is costly, but those problems can double in an EPC, as unachieved savings must still be paid to the energy retailer.

Depending on the cause of the shortfall, they must still be paid to the financier. Your partnership with the ESCO is critical to avoiding this unfortunate scenario. When sufficient measurement and monitoring is part of the programme, the risks decrease dramatically.

If you are looking to implement a NabersNZ rating, or some other energy performance standard, measurement and verification of energy use is an essential step in ensuring you achieve it. If buying new equipment isn’t possible, an EPC will help you generate the expected savings of the programme, and provide the insight you need to identify further opportunities for cost-effective energy savings.

Ewan Gebbie is executive officer of the Energy Management Association of New Zealand. EMANZ provides training in measurement and verification and energy management, and accredits individuals for technical competence through the EnergyMasters programme.