Sense of touch for medical, service and industrial robots

The miniaturised hollow-shaft design for cable and conductor feedthroughs make the haptic sensors particularly easy to integrate. With their high sample rate and resolution, they give robotic systems in medical and surgical applications or assembly and handling technology a keen sense of touch: a change in mass of as little as one gram, for example when manipulating sensitive components, can now be reliably detected.

These innovative haptic sensors with a hollow shaft will be on show at the WITTENSTEIN booth as a complete product portfolio in various sizes, both integrated into application models of robotic hands and medical instruments and as a live demo in a 6D haptic simulator.

Precise measurement, perfect integration

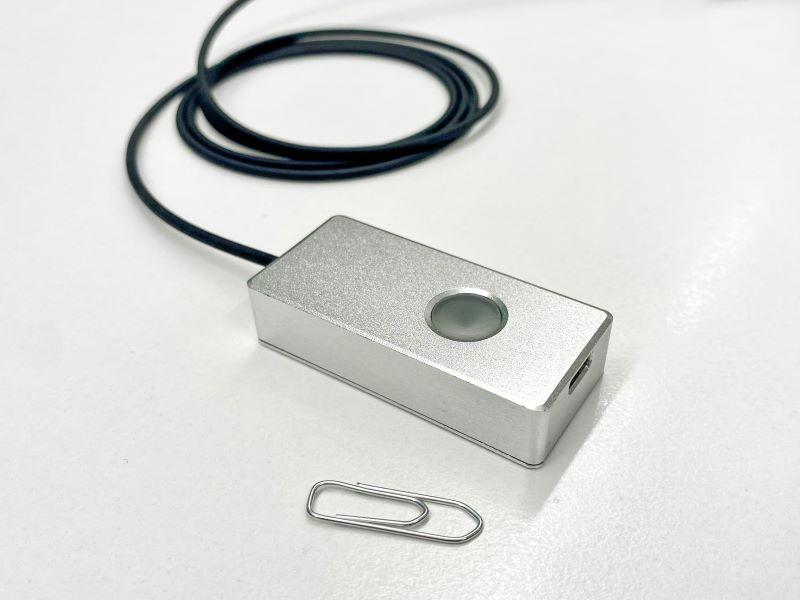

The 6-axis force / torque (F/T) sensors in Resense’s HEX product family, which offer a sample rate of 1 kHz and 10-bit resolution, measure changes in mass in the three translational and rotational spatial directions with the help of integrated strain gauges. The analog voltage signals produced in this way are converted to forces and torques in a compact, external electronics box.

The sensor data can be visualized and recorded in real time, then exported to a control system or application as measured values. Lead customers in industry and university research, in the field of robot-assisted surgery among others, praise the miniaturized hollow-shaft design and the measurement accuracy – features that ensure a high degree of adaptability to the application as well as optimum integration.

Helping to shape future human-robot interaction

Robots integrated into human environments need humanoid capabilities. Resense sensors give robots a special sense of touch, enabling a new era of empathetic human-robot interaction while increasing performance, safety, and precision in areas such as medical, service and industrial robotics.

Positive verdict on the first twelve months:

Resense successfully combines expertise from WIKA and WITTENSTEIN

Resense was set up in April 2023 as a joint venture between WIKA and WITTENSTEIN with the aim of carving out a leading role for itself at an early stage in the future market for haptic sensors. The two partners each hold 50 percent of the shares. Resense has now closed its first fiscal year with a better-than-planned result.

In terms of products, the joint venture is based on the miniaturized hollow-shaft multi-axis sensors developed by a WITTENSTEIN startup for highly precise measurement of forces and torques in confined spaces. As a leading producer of pressure and temperature measuring equipment, WIKA contributes high-tech manufacturing expertise in sensor and chip components.

Developers from Resense and WIKA are working together to develop pioneering processes and technologies, for instance for glass-soldering the novel silicon chips onto the sensor deformation body, bonding hair-thin aluminum wires between chip pads and flexible conductors or laser welding the titanium geometry. The start of production and certification of the sensor technology were initiated in 2023 with the goal of producing large quantities for the industrial market in the near future.

Contact:

Treotham Automation Pty Ltd

www.treotham.com.au