They’re so small that they are easily overlooked. However the importance of air filters – and properly maintained air filters at that – cannot be ignored.

Explaining the benefits of replacing filters on a factory floor, Robert Taylor, Product Specialist for SMC Corporation Australia New Zealand says that filter maintenance is essential for the following reasons:

1. Efficient equipment: “Proper filter maintenance ensures that machinery and processes run efficiently and economically.”

2. Goodbye contaminants: Filter maintenance helps keep contaminants out of cylinders, valves, and other pneumatic components. “This guarantees a longer service life and enhanced product reliability.”

Robert adds that its common for manufacturers to resist the replacement of filters due to dreaded downtime. “For the most part (and depending on the system), this is a general misconception. An air system that runs 24/7 should have a bypass system around the filters, allowing for maintenance downtime to occur without disrupting the air supply,” he says.

“And for those manufacturers that shut down a system at the end of the day (or week), this is the ideal time to replace air filters with minimal disruption to operations.”

“When it comes to the cost of maintaining filtration,” says Robert “one needs to carefully consider the cost of the downtime or lost production that occurs when a component fails during production, through air quality issues. In a food, beverage and/ or packaging environment, for instance, maintenance is critical. Exhausts from the air system are in close proximity to food products and as such there is a risk of products being ‘spoilt’ through contamination that is inevitable when an air filter fails.”

How often should air filters be replaced?

Robert explains that air filters are all designed with a recommended service life. “For SMC’s range, we recommend two years or a 0.1MPa pressure drop as a key indicator for replacement. We have, however, seen shorter time spans in applications demanding longer service hours - so it depends on the environment.”

For instance, a dirty or dusty environment will see the filter becoming contaminated more quickly.

How to tell when it’s time to replace a filter

Robert outlines a few simple signs that one should look out for: “SMC offers a handy visual-cue red and green indicator on the top of the filter that indicates when the pressure drop through the filter is higher than the optimum level. In addition, pressure sensing options can be added to SMC’s modular range for remote monitoring of pressure differentials across filters.”

“If not, look for signs that the machine may be slowing down or not performing as it should be; it will become quite evident in the increase in pneumatic component failures.”

In addition, Robert says that a discolouration in the silencers installed in the valves could also be a dead giveaway. “In the case of very fine oil mist filtration you may start to ‘smell' or feel the oil in the exhaust air.”

Maximising air filtration systems for cost-efficient performance

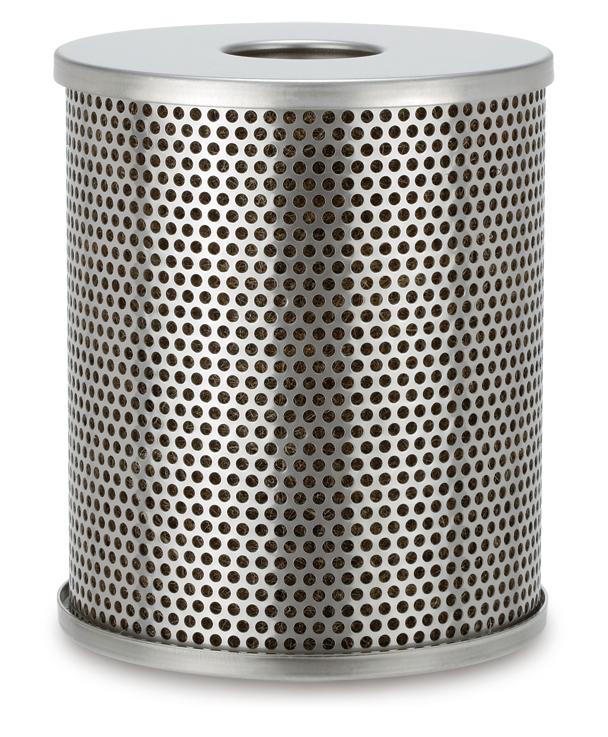

Robert explains that while SMC has a wide range of filters, the AFF main line filter series should be “part and parcel” of every system. “This is a 3 micron or 1 micron filter. This offers a basic level of filtration to ensure that the bulk of the contamination is removed before going into the factory air system. If you suspect that there is condensated water trapped in the plant’s compressed air, you might need to consider adding an water separator to your air preparation system. This is the next line of defense for removing water are drip legs and aftercoolers.”

To conclude, Robert urges manufacturers to strongly consider proper filtration and its benefits. “It helps to optimise the cost and performance of a system. In the compressor room, you should design your filtration to cover off the minimum level required by the factory. This way you do not over-invest in filtering air to a level that may not be required by some of your equipment. The filtration should then be ‘adjusted’ at the entry to a machine that may require a higher quality of air. This, in turn, minimises the cost of the filtration and maximises the performance of your system.”

Website: www.smcanz.com