NIMROD Engineering is a small engineering company based in Hornby, Christchurch that specializes in the manufacture of attachments for excavators, in particular quick hitches.

Being a small firm we are always looking for new innovative ideas in our field to keep us ahead in a very competitive field, says Mark Harrington general manager of the company.

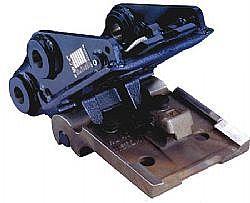

Now we are very excited about the release of a new generation of mechanical quick hitches called the Klac system.

Smaller machine owners have a real need for a practical mechanical quick coupler which will allow them to be more productive yet doesnt cost them the earth, Harrington explains.

In general the problem with mechanical couplers is that the operator must get out of the machine to take a safety pin out, undo a thread mechanism or pull a pin or wedge, then get out again and repeat the process to fit the new implement.

With some systems after the machine has been worked a while the operator needs to get out at least once more to take the slack out. The other problem is that most hitches add length to the dipper which changes the digging geometry of the machine significantly, says Harrington.

Klacs solution is a very innovative design and the beauty of it is in the simplicity of the system. This European design reduces the number of parts and eliminates any need for greasing, adjusting or servicing. To unlock the hitch the operator only has to get out and pull a lever, and then the hitch locks on automatically to the new implement and there is no safety pin!

The way the hitch attaches means that it has two levels of safety built into the design. It complies with all EU standards.

Another appealing fact is that the hitch when fitted follows fairly closely to the machines original geometry, which means very little, if any, break out force is lost.

The main parts are made from cast steel to provide long service.

Hydraulic Klac hitch

The hydraulic version again builds on the simplicity of its mechanical brother.

It utilizes a small single acting cylinder to unlock the hitch, which has the advantage of the machine only needing one hydraulic line. It has another advantage in that you can still operate the hitch as a mechanical hitch if you have a hydraulic line failure.

The hydraulic version has the same size profile as the mechanical version and weight wise will beat the pants off other hydraulic hitches.

The Klac hydraulic hitch also comes with the option of the Klac protect a unique solution to the problem of hitch hose installation.

It is often very difficult to plumb them as there is just so little room, says Harrington. When the bucket is crowed the hoses tend to pinched or poke out the side. On some mini excavators it has been impossible to effectively install hydraulic hitch.

The Klac protect solution to these problems is a sheath that allows the hydraulic hose to lengthen and retract to accommodate the bucket movement.