IMI is launching its first control valve for urea plants, which is set to be installed at one of the major fertiliser plants in the MEA region for the first time later this year.

The newly designed urea valve draws on IMI’s extensive expertise in designing, installing and maintaining valves in power plants and oil and gas refineries, as well as extensive engagement with the industry. The valve is a product of IMI’s Growth Hub innovation engine, which aims to accelerate the development of new products in collaboration with customers.

The fertiliser industry faces wide ranging challenges such as gland leakage, corrosion and erosion of valve internals, as well granulation at lower fluid temperatures. Additionally, the flashing liquid is a particular challenge for the design of urea valves because it impinges on the body or trim parts at higher velocities due to changes in fluid phases.

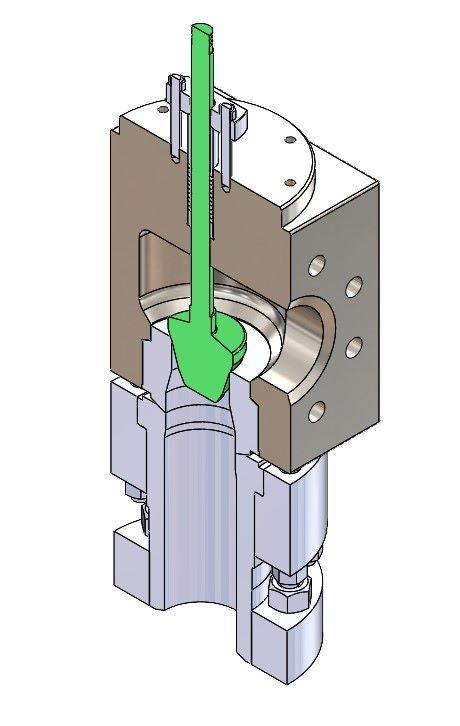

IMI’s solution is designed to overcome these challenges. It features an angle over-the-plug configuration with its straight outlet for the flashing fluid, while a rapid increase of the flow diameter downstream where the fluid expands avoids flashing damage downstream of the valve.

Meanwhile, gland leakage resulting from erosive particulate in the urea fluid scratching the valve stem is addressed with wiper/backup rings that prevent packing failure from granules and hard particles. The innovative rings comprise tough but smooth aramid fibre yarns at the corners, expanded polytetrafluoroethylene (ePTFE) graphite fibre yarn at the faces, and high density extruded and expanded PFTE cord at the core.

As well as being designed to robustly withstand highly corrosive urea with no dead zone in the body, the valve has been designed with ease of maintenance in mind, featuring a split body and integral bonnet.

Jackie Hu, CEO, Automation at IMI, said: “Urea valves pose significant engineering challenges because of their exposure to a highly corrosive substance, which our team has worked hard to overcome. The sector has long grappled with inadequate and obsolete valves. The solution we have proposed has been developed collaboratively with the sector to address the key problems its engineers face.”

To find out more about IMI’s process automation solutions, please visit:

https://www.imi-critical.com/?&utm_source=trade_website&utm_medium=pr.