Although the most conventional use for Infrared Imaging is the location of electrical hot-spots for fire prevention and insurance, there are a myriad of other potential uses in industry, R&D and manufacture.

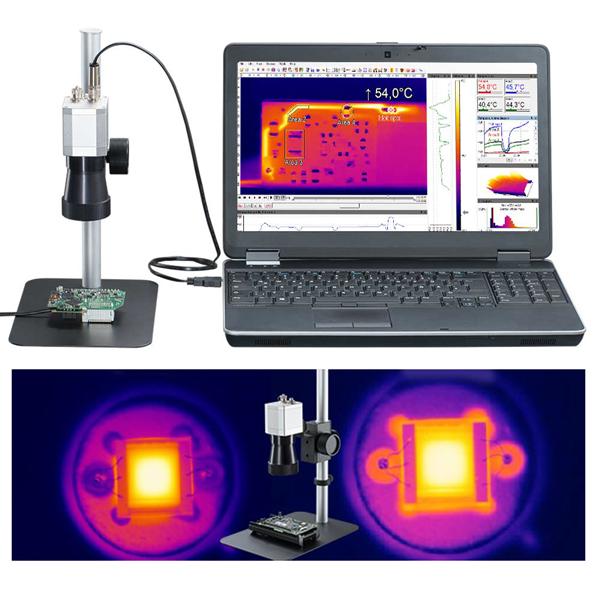

Late last month, a new accessory for a special application was released, the microscope lens attachment for viewing small objects such as integrated circuits or LED’s.

It’s worth thinking about installed, thermal imaging cameras that may be used for countless applications from checking tank level, cooking surfaces, vegetable temperatures on a conveyor and hot-metal detection.

Another growth area for Infrared is for use in Unmanned Aerial Vehicles (UAV) or drones. Special lightweight versions of these camera are available for this use and have been deployed for study in Antarctica, looking at plant growth in a field, inspection of solar farms and powerline inspection.

New developments in industrial cameras include special types for hot metal detection or for measurement of glass. Conventionally glass presents a problem for IR cameras as is completely opaque to these IR frequencies, and also emits very little infrared.

Special frequency cameras allow glass to be transparent to the infrared so that a camera might be in a clean office looking out into a dirty foundry environment through a glass window. Also, if one is in the glass industry, then special frequencies allows the IR cameras to be used to measure glass sheets or bottles with a high degree of accuracy.