Kaeser Compressors will demonstrate the benefits that Industrie 4.0-ready compressed air technology has to offer at the forthcoming National Maintenance Engineering Conference.

Industrie 4.0 – or the fourth industrial revolution – presents a new era of manufacturing led by a number of cyber-physical systems. As a leader in the engineering of compressed air technology, Kaeser says its products and services are not only designed to deliver the most reliable, efficient and cost-effective compressed air supply possible, but they are also fully ready to take advantage of the future-oriented benefits that Industrie 4.0 has to offer.

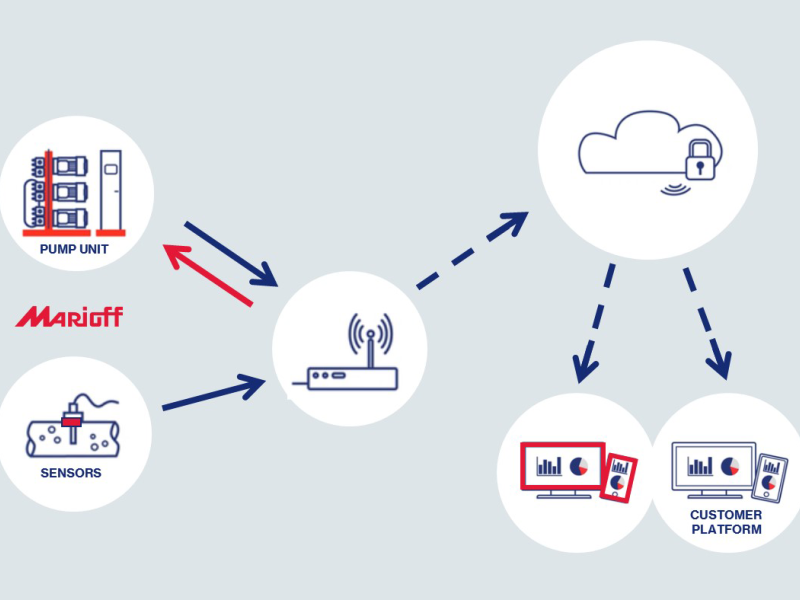

In the ultra-flexible Industrie 4.0 production environment, intelligently networked compressed air systems provide the optimal compressed air power and quality required. Moreover, potential issues within the compressed air network are identified at a very early stage so that appropriate service measures can be taken before a fault even occurs.

Visitors to Stand 33 will be able to learn more about a number of Kaeser 4.0 products and services that can seamlessly be incorporated into a production or energy management system. This includes the Sigma Air Manager 4.0 (SAM 4.0).

A key technology in the advanced world of Industrie 4.0, SAM 4.0 is a cutting-edge compressed air controller and the central mastermind that controls the entire compressed air supply system. Via IoT (the Internet of Things), the SAM 4.0 is responsible for data streaming to a centralised application in real-time via the powerful Ethernet-based Sigma Network. Here the parameters are analysed, processed, supplemented with expert knowledge and output to various mobile end devices.

Monitoring key operating parameters ensures that compressed air system efficiency can be kept in the optimum range at all times, and thanks to real-time transmission and evaluation, data is always as up to date as possible.

A key advantage of Kaeser 4.0 compressed air technology is the unprecedented efficiencies that can be achieved. Jeff Coyle, National Design & Engineering Manager at Kaeser Compressors Australia, will be speaking on this topic at the NMEC conference. In addition, Coyle will review what the current ISO standards for compressed air quality are, who they might apply to and how different compressed air treatment technologies can assist in meeting them.

Details, www.kaeser.co.nz, 0800 447 820.