The food and beverage industry requires water for various applications within its manufacturing facilities, notably as an ingredient, where it must be free from undesirable taste, odour, colour and impurities that could be harmful to consumers and to the product quality.

To help its customers comply with the most stringent regulations and guarantee the quality and consistency of the water which enters their products, SOLYS has developed NURION, a reverse osmosis system that produces ingredient water for infant formula and soft drinks.

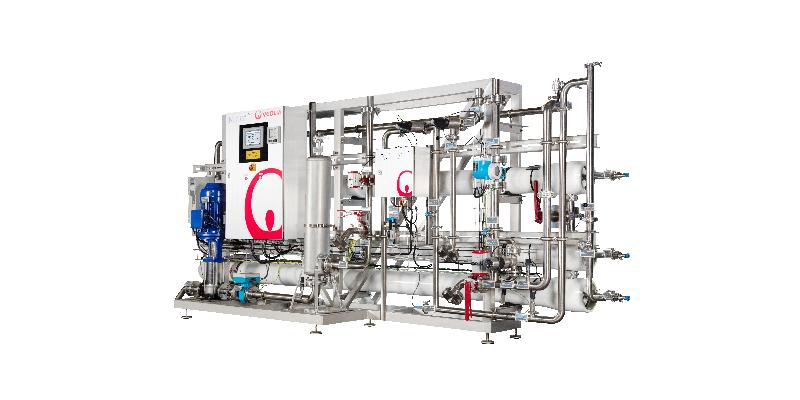

NURION ensures water quality consistency thanks to its permeate line design and certified components, which follow EHEDG hygienic design principles to optimise microbial control throughout the treatment process. The equipment pipes are made entirely of stainless steel, with a variable speed pump integrated with automatic control valves, aligned with the automation features ensuring a stable operation and an autonomous reverse osmosis. In addition, all non-metallic materials (pressure vessels, membranes, sealings/gaskets) are in accordance with at least one of the drinking water FDA/NSF-61/ACS regulations.

Within the NURION range (permeate flow-rate from five up to 25 m3/hr), SOLYS is proposing a global offer, ensuring high equipment reliability and giving flexibility through different options:

• Full standard treatment line including pre-treatment.

• Complementary products: Cleaning in Place (CIP) and chemical dosing sets.

• Piping and installation kits.

• AQUAVISTA line of cloud-based digital solutions for plant performance optimisation.

• Consumables, spare parts and emergency service kits.

• HYDREX line of water treatment chemicals.

• After-sales services.

Details, eaton.com