Off the back of a challenging year to date, a new snapshot looking at the performance and priorities of some of New Zealand’s mid-market manufacturers shows a brighter business outlook and increased economic optimism for the months ahead.

Commissioned by MYOB, the latest Mid-market Snapshot reporting on a sample of mid-sized manufacturing businesses, revealed that while 44% of the New Zealand manufacturers surveyed reporting a drop in revenue on a year ago, more than a third (39%) say they’ve seen an increase – and further insights indicate that this upward trajectory is expected to continue.

Nearly 7-in-10 local manufacturers polled predict that their revenue will be up in the next 12 months, and more than half (55%) surveyed say they have more work in the pipeline for the next three months than they would usually expect at this time.

Jo Tozer, MYOB Head of Go-to-Market says the increase in positive sentiment around both business performance and economic outlook is encouraging as we head toward a new year.

“While we know mid-market businesses tend have continued to have a slightly more positive economic and business outlook compared to their SME counterparts, the past few years haven’t been without their challenges.

“The ongoing repercussions of the pandemic, the increased cost of goods, disruptions to supply chain and increases in the cost of their business overheads are all issues manufacturers we surveyed said are impacting their business at the moment and ones they expect to continue to effect things over the next six months,” she adds.

“However, with our insights showing many are investing in future-proofing their business, an increase in adaptability, productivity and resilience that comes from doing so will be helping to bolster their confidence as they look to capitalise on increased sales volumes in the months ahead.”

Innovation driving growth

In terms of what’s propelling these businesses forward, many manufacturers surveyed have seized the opportunity to do things differently.

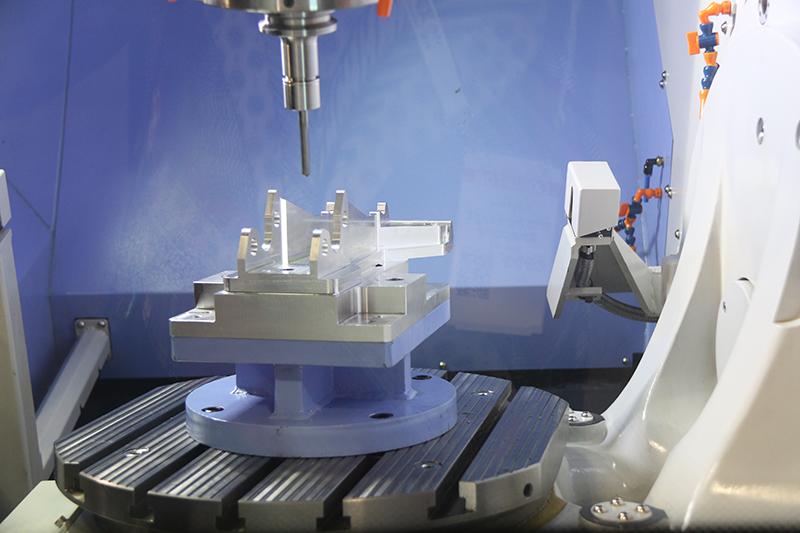

Almost two thirds (64%) of the New Zealand manufacturing businesses surveyed said they have invested in innovation for their business over the past 12 months, with key areas for investment by this group including: new software solutions to manage their business (52%), more automation of manual processes (51%), improving production lines (41%) and tightening or improving supply chain (39%).

Building on this momentum, innovation also remains firmly on the radar for the year ahead with more than 7-in-10 surveyed saying that innovation is a key priority for their business.

For these businesses looking to innovate their operations in the next year, the majority (51%) plan to tighten or improve their supply chain, while almost half (49%) want to improve their production lines, and 44% want to expand their services to customers and clients.

“For businesses that want to thrive in any environment, innovation is absolutely key and the manufacturers we surveyed clearly recognise the meaningful impact changing their business approach and investing in innovation can have on their performance moving forward,” explains Jo Tozer.

“Almost three quarters of those we polled who plan to innovate in their business over the next year said they’re doing so to improve bottom line, while nearly two-thirds believe their changes will streamline operations and almost half of this group acknowledged it will help their teams get time back to focus on other things.

“All of these potential outcomes are absolutely critical to a business’s success and manufacturers taking steps to achieve these ambitions will have a real edge,” Jo says.

Looking ahead

In addition to driving their own changes through innovation in their businesses, many local manufacturers appear to be gearing up for changes in the industry more broadly. More than half (59%) of New Zealand manufacturers polled for the Snapshot believe the industry will rapidly change over the next five years.

Amongst the biggest changes likely to shape the industry over the next five years, the most common responses from this group included: More competition (85%), more automation (62%), more customisation (62%) and the prospect of bigger businesses buying up smaller businesses (45%).

However, change is already upon the sector, with three quarters of mid-sized manufacturers surveyed stating they’ve seen a rise in the need for customisation – a trend which is likely to influence business approaches moving forward.

“As both the business environment and the customer needs continue to change, it’s likely we’ll see manufacturers continue to evolve their approach to their production workflows and their business operations systems to meet this demand. Digitisation of their business management systems is certainly a consideration here, with 60% of those we surveyed saying they’d like more than half their business to run using digital technology in future,” says Jo.

“With one-in-five mid-sized manufacturers we surveyed saying they had turned down customers because their current systems don’t enable them to deliver to their requirements, it’s clear there’s an opportunity to grow their pipeline even further – one which they can’t afford to be missing out on.”

For more insights around the performance, ambitions and priorities for mid-market manufacturers in New Zealand and Australia, MYOB’s ‘Making Advances’ report can be found here.